Wondering which type of welding gun works best for you?

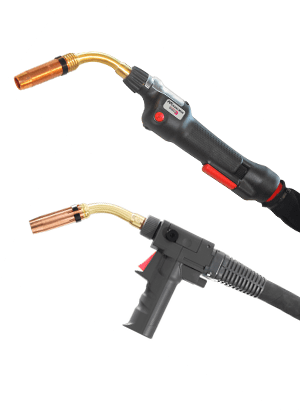

We produce several products with options to optimize the most common welding processes and positions. Our manual product technology includes air-cooled, water-cooled, and flux-cored. Depending on manufacturing needs, we offer customized options for certain volumes of businesses with adjustments to features including custom neck lengths and bends.

The manual MIG and push-pull selection is made to maximize customization and the needs of welders on the job. They are designed to deliver on three key promises across all product lines.

Comfortable

When welding isn't comfortable, it can be hard to stay focused for long periods. That’s why our MIG, TIG, push-pull, and flux-cored guns are designed with ergonomics, flexibility, and responsiveness in mind, tailored to meet the physical demands of a welder's day-to-day work.

Our lightweight BIKOX cable reduces cable weight by up to 30%, enhancing comfort and ease of movement.

With more trigger and custom neck options, your welders can work in positions that feel natural to them, boosting both comfort and productivity.

Swivel joint necks allow for better angle manipulation in tight weld joints, making challenging welds easier to tackle.

Durable

For fabricators and manufacturers, it all comes down to the bottom line.

What kind of ROI can a new piece of equipment deliver?

Potential customers want to know if it will save their budget in the long run.

Your tools need to not only feel good but also withstand the harsh demands of an industrial environment.

We build our products to endure. That means crafting durable welding components, from the handles to the precision parts like consumables.

Attention to detail, such as reinforced ribbing on the handles, ensures every part stays in peak condition, ready to meet the daily demands of tough jobs.

Maintenance-friendly

The easier to maintain, the less downtime.

Easily disassemble, service, and re-assemble with minimal tools and avoid complicated processes.

Innovate features like single-piece diffusers & tip holders for our air-cooled products reduce the requirement for a large parts inventory and lower maintenance frequency.

Changing more intricate parts like a torch cable swap or handle replacements is also made easy with simple tools like torx bits and crescent wrenches.

For the water-cooled selection, we offer an in-house repair program where experienced in-house technicians can refurbish and return in like-new condition.

The Right Tool for the Job Makes All the Difference. We Make Sure You Have Options.

At ABICOR BINZEL, we understand that the quality of your work relies on the quality of your tools. That’s why we provide a comprehensive range of manual and automated welding solutions, including MIG and TIG torches. Our products are engineered for precision, durability, and comfort. Discover our selection and find the perfect tool to elevate your productivity and craftsmanship.

Explaining the Different Types of Welding Guns

Air-cooled Welding

- Naturally cooled by the shielding gas and ambient air

- Duty cycle typically not to exceed 60% for CO2 applications

- Lighter in weight, lower in cost

- Amperage load up to 400 amp (some models higher)

- Very low maintenance

- Most common type used - capable for light to medium duty fabrication

Water-cooled Welding

- Uses coolant lines to lower operating temperature

- Duty cycle high - commonly 100% - for heavy fabrication and thicker metal applications

- Amperage load up to 600 amp

- Superior consumable life from lower operating temperature

- Higher cost, heavier weight

- Must be paired with a welding cooler to circulate coolant

Push-pull Welding

- Used in aluminum welding applications to assist in wire feed

- Air and water-cooled options

- More maintenance-intense than standard welding guns

- Uses specialized motors and drive rolls within the gun handle to feed wire precisely

- Higher in cost

- Heavier to operate for welders

Fume Extraction Welding

- Specifically utilized to capture weld fume at the weld arc

- Air and water-cooled options

- Special shroud collects smoke at nozzle while welding

- Pairs with a fume extraction system

- Welder technique and position important to capture fumes

- Comparably priced to water-cooled welding guns

Flux-cored Self Shielding

- Ideal for outdoor use on construction sites, pipelines, railroads, etc.

- Current extends all the way to the contact tip

- Allows for wire feed welding when conditons like wind make GMAW welding impossible

- Don't require additional shielding gas tanks

- Does not require a gas line

- Air-cooled only

Parts Breakdown

Depending on the product, your parts breakdown might be a little different. In some air-cooled solutions, we combine the diffuser and contact tip holder into a single part.

If fume extraction is more aligned with your application, you will require an extra part on the front end called a shroud or suction nozzle to effectively capture fumes.

Push-pull welding utilizes drive rolls and motors. While this adds extra weight and can be uncomfortable, it is a necessary design element to reliably feed aluminum wire from the feeder to the contact tip.

Contact Tips

Our patented and precision-made contact tips are designed to limit common welding pain points: microarcing, burnbacks, and wire wandering.

Our contact tip construction process results in a smoother bore for better wire delivery and current transfer.

Material grade ranges from standard copper to silver-plated.

Nozzles

Nozzles deliver gas to the weld piece.

The more durable, the better.

Our nozzles are made from high quaity brass and utilize nickel-plating for select models, to hold up more in industrial environments.

Our two-piece nozzle design for most air-cooled models lessen part inventory and extends usage.

Wire Liners

From steel to insulated to specialized thermoplastics, we make liners in a variety of materials to ensure smooth feed and minimal downtime.

We utilize a floating liner that requires precise cutting with welpers. No set screw required.

Check your welding gun model and weld wire material for recommended liner type.

Diffusers and Insulators

Our air-cooled welding guns use a special combo diffuser/contact tip holder that lessens inventory needs and overall part spend.

For water-cooled models we have insulators in standard and high temperature versions to hold up against your most extreme demands.

Check insulators often to ensure no damage from torch abuse.

Can Your Welding Guns Connect to My Power Supply?

Yes! All ABICOR BINZEL products are made to order and are almost guaranteed to connect to your welding power supply.

Our equipment is specifically designed to interface with industrial-grade welding machines. If you're using a hobbyist-style machine (one with a rating below 200 amps), the power pin housing may not fit perfectly into the rear connection. Please contact us for more details.

Below is a list of welding machine manufacturers we commonly accommodate

Lincoln®

- POWER MIG®

- Lincoln 7 Style

- Lincoln 10 External Gas Style

Miller®

- Millermatic®

- Multimatic®

Hobart/Tweco®

- ESAB Welders

- Hobart Welders

European-style

- All European style welding machines (EWM, Everlast, etc.)

"The way the ABIMIG feels in your hand is lightweight, ergonomic, less stress on your wrist... and it's a bonus to have good consumables to go on the front end."

- Jameson Jalbert, Lead Welding Instructor, Lake Area Technical Institute

Lake Area Technical Institute - Watertown, SD

The award-winning Lake Area Technical Institute is more than just a welding school. It is a two-year master class in metalworking preparation.

When Lake Area Technical was looking to change MIG welding torches, they were searching for a solution that would enhance the student experience while creating superior value in terms of consumable life, safety, and comfort. They found it with the ABIMIG air-cooled line of torches.

In 2017 the welding school at Lake Area Technical has switched completely to the ABIMIG AT Lightweight MIG guns for their MIG welding leads.