Tactile Laser Brazing and Welding

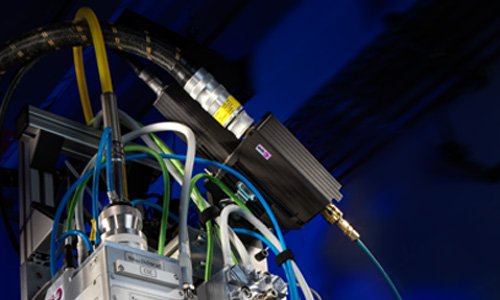

MPH-T Adaptive Laser Brazing System

The MPH-T (Multi Process Head - Tactile) laser processing head with integrated tactile seam tracking is capable for CW-Laser in the 880 -1070 nm range. The tactile seam tracking process allows the MPH-T to find the beginning of the seam accurately and guide the process along the seam. Component allowances with MPH-T are automatically balanced. The independent system with seam tracking integrates with every guiding machine and is controlled by digital In-/Outputs or Interbus.

MPH-T comes optionally equipped with the Lessmueller WeldEye package, a fully integrated imaging process monitoring system consisting of a coaxially integrated camera and process lighting. The system is completed by powerful evaluation electronics, which is able to process the image data in real-time.

Metal and Joint Profiles:

- For steel and aluminum

- Y-seam at flange welds

- Fillet weld at the Lap joint or T-joint

Acceptable Lasers:

- Diode laser from Laserline

- Solid-state laser-like rod laser or disk laser from Rofin or Trumpf

- Fiber laser from IPG

MPH-T Features at a Glance:

Laser Brazing at it's Most Precise and Efficient

Lessmueller Monitoring System - Fast Setup & Boost Productivity

The MPH-T comes equipped with a slew of technologically advanced features to make the brazing of complex assemblies reliable and efficient, including:

- Telescoping arm TA-Fix

- Telescoping arm TA-Motion

- Inclination Sensor

- Zoom collimation (Autofocus)

- Highly precise tool changer

- Hot-wire up to 100 or 230 A

- Profinet, Ethernet, etc.

- Field Changeable Optic Modules

- Full Scale adaptability for brazing and welding

- 10+KW laser power capable

- Easy integration with Abicor Binzel Masterfeed offerings

In the light of automated systems, short cycle times and low error tolerances, the WeldEye process monitoring system from Lessmueller ensures the quality of workpieces, prevents expensive reworking or rejects and thus makes a decisive contribution to productivity.

WeldEye works as an integrated imaging process system. This system consists of a coaxially integrated camera with process lighting to get reliable imaging of the brazing process.

These high-tech cameras and powerful evaluation electronics transmit all vital information about the process continuously and in real-time for perfect seams — and optimally controlled production.

WeldEye can work either independently or integrate into the MPH-T Tactile Laser Processing Optic.

MPH-T Product Videos:

| Weight | 20 kg |

| Dimensions (L x W x H) in mm | 100 x 200 x 300 |

| Laser protection class | 4 |

| Wave length | 880 - 1070 nm |

| Working space | lateral Y: +/- 15 mm, height Z: +/- 10 mm |

| Laser power | for CW-Laser until 6 kW |

| Focal length | 141 - 250 mm |

| IP-class | 67 |

| Power supply | 24 V / 10 A |

| Parameterization | via Ethernet |

| Connection | different manufacturer for wire feed |

| Special features | cover slide drawer, integated crossjet |