The technology package from Blackbird Robotersysteme GmbH comibnes sophisticated control technologies, highly dynamic scanner systems, optimally adjusted optics and outstanding user-friendliness. With this complete system everything simply fits when it comes to laser welding.

Solutions offered by Blackbird - At a Glance...

Blackbird Scanners

Beyond the Scanner...

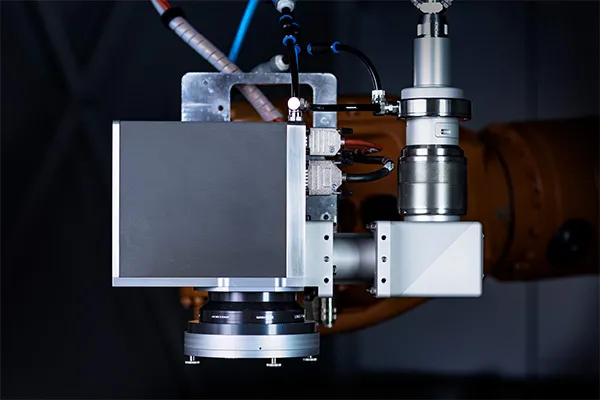

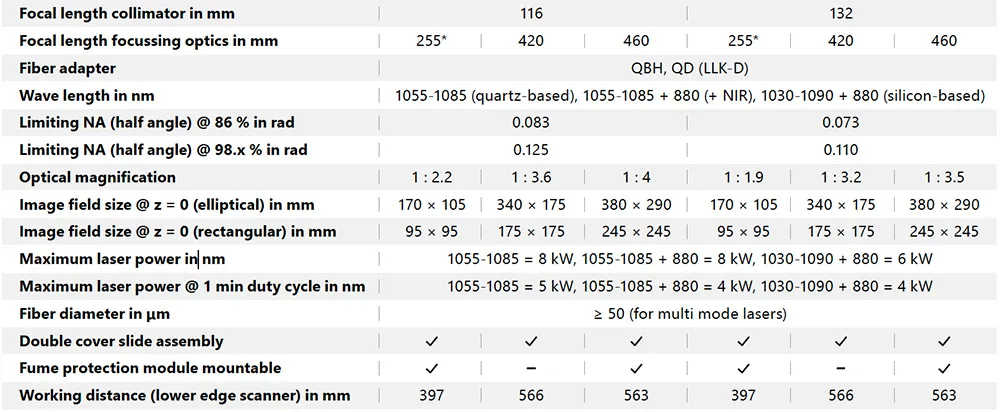

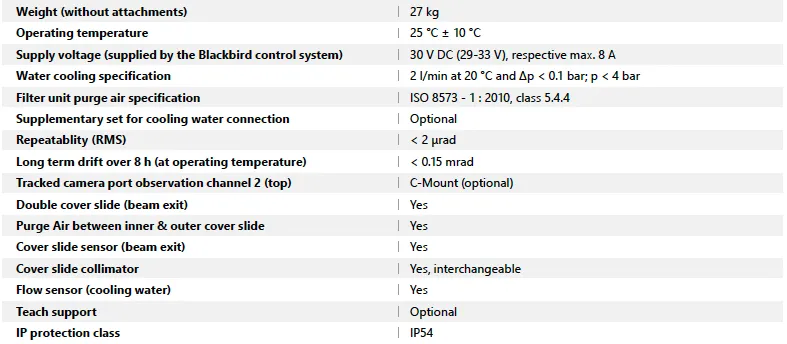

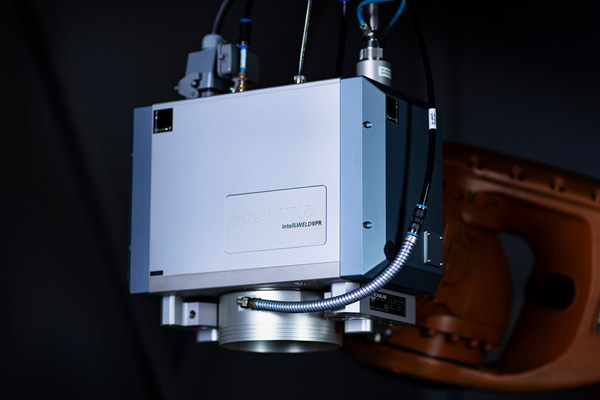

intelliWELD II PR

The scan system is designed for the on-the-fly operation, in which a handling device moves it in a simply programmed path over the component to be welded and the welding task is carried out simultaneously.

The intelliWELD II PR deflects the laser beam quickly, precisely, and with high repeatability. The fast movements of the deflection mirrors increase the processing speed and reduce the positioning time from weld seam to weld seam (jump time) to a few milliseconds. This increases productivity significantly. The optional superimposition of a welding figure with oscillation geometries enables the welding result to be optimized even with complex tasks.

The compactness of the intelliWELD II PR enables it to be used and installed in a wide variety of industrial environments, whether with robots, linear axis systems, or compact production systems. The optics are optimized for fiber-coupled disks or fiber lasers with powers of up to 8 kW.

The pre-focus optics of the intelliWELD II PR enable obtaining a high beam quality. “Vision“-based applications can achieve particularly good results due to the low transmission loss and the highest imaging quality. These advantages come into their own in fillet welding with precise edge tracking.

intelliWELD II PR Options and Extensions

On-The-Fly Welding

On-The-Fly welding allows the scanner or the component to be moved during the welding process. This reduces the processing time to the shortest possible and increases the system's efficiency. The blackbird controller can perform OTF welding in conjunction with robots (e.g. KUKA, ABB, or Yaskawa or with one or two linear axes.

Optical Coherence Tomography

The addition of an OCT scan system to the intelliWELD II PR can add quantifiable value to the process. This ranges from finding the edge and tracking the weld seam to detecting the weld depth. The final check of the welded seam makes the OCT the universal genius of measuring systems.

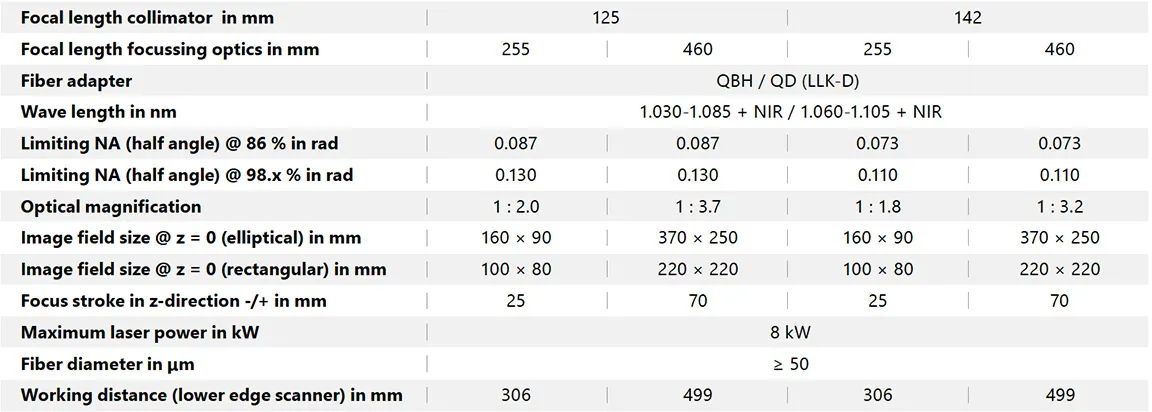

intelliWELD II FT

The scanner is designed for on-the-fly operation, in which a handling device moves the scanning system in a simply programmed path over the component and the welding task is carried out simultaneously with the movement. The intelliWELD II FT deflects the laser beam quickly, precisely, and with high repeatability. The fast movements of the deflection mirrors increase the processing speed and reduce the positioning time from weld seam to weld seam (jump time) to a few milliseconds. The optional superimposition of a welding figure with oscillation geometries enables the welding result to be optimized even with complex tasks.

The intelliWELD II FT offers the possibility of realizing variable spot diameters and thus flexible seam widths, making it particularly suitable for overlap welding. The optional zoom function allows the user to vary the spot size during the welding process. The optics are optimized for fiber-coupled disks or fiber lasers with power outputs of up to 8 kW. Real-time monitoring of all key scan system status parameters is checked and displayed in the Blackbird software.

intelliWELD II FT Options and Extensions

On-The-Fly Welding

On-The-Fly welding allows the scanner or the component to be moved during the welding process. This reduces the processing time to the shortest possible and increases the system's efficiency. The Blackbird controller can perform OTF welding in conjunction with robots (e.g. KUKA, ABB or Yaskawa or with one or two linear axis.

ScaVis Camera System

With the ScaVis camera system, the component position can be recorded in static applications and used to correct the seam position. The Blackbird OCT system complements the system with seam tracking and inspection for on-the-fly applications

intelliSCAN FT

This 2D scan system with F-Theta optics and mechanically adjustable collimation is suitable for both static welding applications and portal machines. The intelliSCAN FT guides the laser beam quickly and precisely along a 2D contour. The compact design, which supports both straight and angled (90 degrees) collimators, simplifies integration into machines with limited space. The optics of the scanning system are designed for fiber-coupled disks and fiber lasers with a maximum power output of up to 8 kW. SCANLAB‘s fully digital iDRIVE technology enables real-time monitoring of all important status parameters of the intelliSCAN FT. The scan system is equipped with an additional internal sensor system for automatic self-calibration (ASC). This smart reference system enables quick calibration of the galvo drives. Occurring drift effects can thus be actively compensated.