Fume Extraction Solutions

Fume extraction solutions are essential for protecting welders from harmful welding fumes and ensuring clean, breathable air in the workplace.

Designed to capture fumes directly at the source, our advanced fume extraction welding systems prevent dangerous fumes from spreading beyond the welder’s station. This not only enhances the safety of welders but also improves overall air quality for all workers in the plant, promoting a healthier and safer working environment.

Fume Extraction Products

xFUME® Fume Extraction Solutions offer enhanced safety across various welding applications, including yours. We provide fume extraction products for both manual and robotic welding operations, ensuring that fume extraction—a critical aspect of every welding process—is both easy and effective.

Fume Extraction Solutions

As workplace safety standards for welding have risen, the demand for innovative solutions has grown. Fume extraction is now at the forefront of these changes, as many plants focus on preventing the spread of harmful fumes that can compromise the work environment.

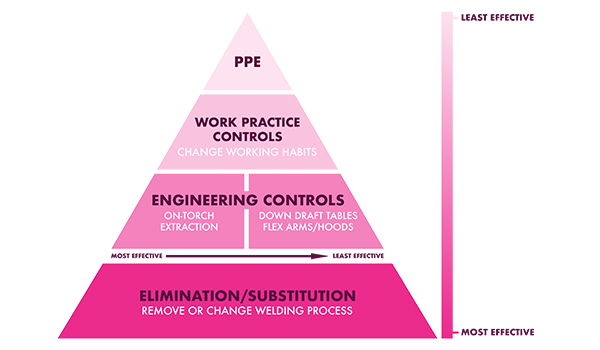

We believe that source capture fume extraction welding is the most effective way to minimize weld fume exposure and protect your most valuable asset: your people. Source capture involves extracting welding fumes directly from the arc and filtering them through a nearby fume extraction system. This approach prevents fumes from spreading to other parts of the plant, reducing the risk of exposure to workers.

The key to minimizing fume exposure is to extract fumes from around the welder's breathing space. Our systems are designed to clean your facility by targeting fumes at the source of welding and capturing any that might escape into the air. We offer comprehensive solutions for all fume extraction welding needs and are committed to leading the way in safety-driven advancements for the industry.

Expert Statements: Fume Extraction

Etienne Blouin, Director of the Environmental Systems Group for Abicor Binzel USA, sits down to discuss the importance of welding fume extraction, some misconceptions, and how to get started with fume extraction in your facility.

Fume Extraction Welding Equipment

Capturing harmful welding fumes directly at the source is the most effective way to maintain a clean and safe environment in your facility. To achieve this, having the right equipment is essential. ABICOR BINZEL offers a wide range of welding products tailored to meet various fume extraction needs.

A fume extraction MIG gun allows welders to work closely with the weld without disrupting the operation. This high-static-pressure equipment optimizes fume capture by extracting welding fumes directly from the arc, rather than from the surrounding area. This is especially crucial when welding at higher parameters, as increased weld power leads to a higher concentration of metal particulates. Such equipment is vital in preventing harmful welding fumes from spreading beyond the welder’s station. We believe this is the most effective approach to capturing weld fumes, and our fume extraction solutions are designed with this in mind.

When extracting fumes from the source, the captured smoke needs to be transferred elsewhere. Typically, the fumes travel through a ventilation system. You have the option to connect a fume extraction MIG gun to a portable vacuum system for easy, user-friendly operation. Alternatively, if not using source fume capture, an overhead hood can be used. Connecting a fume extraction MIG gun to a portable vacuum system ensures your facility's quality and safety exceed industry standards, making it the optimal solution for welding fume extraction.

For plants new to fume extraction, an overhead hood is a good starting point. This equipment is easy to use and requires minimal setup. However, the downside of overhead hoods is that they can allow fumes to spread beyond the welder’s immediate breathing area, exposing the entire plant and other workers to harmful fumes. Our goal is to eliminate this risk by offering welding equipment designed to integrate seamlessly with source capture systems.

The introduction of robotic fume extraction welding has further enhanced our fume extraction solutions. Robotic fume extraction equipment is a newer innovation in the industry. Our system works similarly to our fume extraction MIG guns by capturing fumes directly at the source without interfering with the welding operation. With a sleek design and easy installation, our robotic equipment offers optimized capabilities for high-performance smoke extraction in welding.

The best fume extraction solution for your application may vary depending on the process, material, or part size. ABICOR BINZEL provides a comprehensive range of turn-key fume extraction solutions to meet a wide variety of needs.

.

Source Capture Fume Extraction Explained

Welding Fume is Very Dangerous to Industrial Workers

Weld fume consists of metal, process gas, and non-process gas to form a toxic air that rises, spreads, and is easily inhaled.

A study from IARC, the International Agency for Research on Cancer, classified weld fume as a Class I carcinogen in 2017, meaning welding fume is a known cause of cancer.

Local and national governments are increasingly enforcing more stringent air quality requirements to protect industrial workers.

A cleaner and safer environment not only protects industrial companies from liability, but it helps your workforce be more productive and attracts quality people to your company.

The Closer to the Arc Weld Fume is Captured, the Less it Spreads

Many of the more well-known fume extraction solutions are positioned far away from the source of the weld fume.

These measures do a good job of funneling out dirty and hazardous weld smoke, but are not able to protect the welder directly.

However, these solutions fit too far between the worker and the weld fume to protect them from breathing in these dangerous fumes.

As engineered solutions catch weld fumes closer to where it begins, the ability to limit it's spread increases.

This is why our solutions focus heavily in the most concentrated areas, where they can make the greatest impact, often at a lower cost.

Weld Fume is Best to Address at the Welding Arc

Fume extraction welding guns are not new technology. But the way they work today is.

Modern engineering has allowed us to know more about the type of static pressure needed to effectively capture weld fume depending on your parameters and your welding process.

The more restriction and the higher the parameter = the more suction power you need.

This means you need to have an adequate amount of pressure to capture those concentrated weld fumes without affecting shielding gas and without compromising the welder. Enter ABICOR BINZEL xFUME® extractoion.

Got Questions on Fume Extraction?

There’s usually a question of whether all that additional design and engineering that goes into these fume guns affect the performance of the gun itself.

Is there a loss of amperage? Will it fatigue my welder more? We answer those concerns below.

While it is argued that fume guns don’t ‘perform’ as well, the answer is no, you won’t sacrifice any performance. Today’s fume extraction welding guns perform just as well as regular welding guns with capacities from 200 to 500 amp air and water-cooled for almost every possible situation a standard MIG gun handles. The guns also feature the same range of features as in a standard MIG gun.

Fume guns have been really sensitive to creating porosity from the vacuum sucking up the shielding gas and replacing the gas with oxygen. This in the past has caused a lot of bad welds and a lot of reworking which undercuts the investment into fume extraction guns and extractor systems.

You want to make sure all the vacuum you apply is not reaching the zone where the shielding gas should be. If you measure turbulence near the end of the shielding nozzle, then your flow is too strong or your shroud too close to the welding operation.

Yes, some systems do offer adjustable or dual-flow set-up. Check with whichever company you consult with on fume extraction solutions to see if they offer it.

Fume extraction units for ABICOR BINZEL's fume extraction systems do have an adjustable flow feature.

This is a great question because there are fume extraction guns that can be heavy and bulky to handle, which can affect welders’ stamina. But, even the strain of using a fume extraction torch would depend on the gun you’re changing from and the smoke gun you’re picking, because there are fume guns out there that achieve the same feel and handle as most MIG guns on the market.

It’s also a matter of welding positions. Overhead and vertical welds by their very nature are more straining weld positions than horizontal or down welds, so heavier fume extraction guns could be more strenuous and adversely affect performance because if the welding gun isn’t positioned properly it won’t capture the fume as much as it could.

However, these concerns and the guns’ performance again depends on the MIG gun being switched from and the fume gun in question. Take a demo and see if the difference is real.

You can find plenty of MIG guns out there with the swivel at the base of the cable, and there are plenty of cables out there that weigh the same as many non-fume extracting MIG torches on the market. Do your research and talk to your welding supplier or a qualified rep.

This was a common issue with the first generation of fume extraction guns. In order to fit all the additional components into the first fume extraction guns, there was a significant amount of added weight that made the gun bulky, heavy, and cumbersome to handle.

Today, with a much-increased focus on weight reduction, welder access, and torch ergonomics, modern fume guns are far more comfortable and welder-friendly tools. So much so, that some fume guns, including our own xFUME™ / RAB torch line, are actually less in weight than comparably rated, non-fume extraction MIG guns. Weld.com has a great YouTube video that covers the fume extraction weight question.

The only additional consumable a fume extraction gun requires is the fume shroud.

Other than that, you’re using the same setup as a regular MIG welding gun: diffuser, tip holder, contact tip, and nozzle.

Consumables such as the diffuser, tip holder, and contact tip are the exact same for regular BINZEL MIG welding gun as our fume extraction torches (nozzle may vary depending on fume extraction gun model). And for most other manufacturers it is also the same.

In short, no. Fume extraction guns handle any wire – whether flux-cored, metal-cored, or solid wire. However, depending on the wire used there can be more smoke produced, which is a consideration and an item to evaluate as you look at all the options with fume extraction solutions. With metal-cored and solid core, you will be looking at higher parameters normally as well as hotter gas mixes, which will translate to faster traveling smoke and more difficult welding positions to do fume extraction with for a source capture solution.

Metal-core presents one of the common misconceptions of fume extraction welding. For some, it is believed that welding metal core wire with a clean gas mix (i.e., CO2) creates a ‘clean’ smoke that doesn’t need fume extraction. This is a common myth. Toxic particles will still be released into the atmosphere from the base metal and from the wire as it melts to join into the weld joint, and without proper fume extraction equipment and procedures in place, your welders and the rest of your workers will breathe it in and be adversely affected by it.

Flux-core wire produces a very thick and visible smoke when being welded with. It also releases a lot of particulates into the atmosphere that you would want to catch at the source so as it wasn’t breathed in by your workers. Flux-core also is generally used for low parameter welding, which makes it very easy to extract at the source because lower parameter means slower smoke travel.

Which Fume Shroud is Best?

Product Overview: xFUME® Fume Extraction MIG Torch

Recommended Reading:

- Fume Extraction System Problems and Solutions

- How to Test Your Fume Extraction System

- 5 Fume Extraction Questions You Should Know Before Starting

- Fume Extraction Units: Tell a Good One from the Rest

- Fume Extraction Filter Review: Picking the Best Filter for the Job

- 3 Problems with Contact Tips (and How to Overcome Them)

- Understanding Contact Tips