Fume Extraction Welding: The Complete Guide

Fume extraction welding is an increasingly in-demand solution for industrial manufacturers looking for air quality control. Protecting your welders and other workers within the plant, combined with the increased research linking weld fumes to maladies like

cancer, make fume extraction a necessity more than a luxury now more than ever. So where do you begin? What are the options? And which option is right for you? In this free guide, we'll cover the different options available, what performance metrics matter, and why source

capture fume extraction is the most effective method. If you're a Safety Officer, Industrial Hygienist, Production Manager, or Manufacturing Executive, you will want to read this resource before moving ahead evaluating Fume Extraction welding solutions.

Want the Printer Friendly PDF? Click the Button Below to Download:

Table of Contents

-

Introduction to Fume Extraction

What Fume Extraction welding is and why it might be for you -

What is Your Current Welding Process?

Metals, your parameters, respirator masks, and health impacts -

Fume Extraction Welding Solutions

Fume guns, robotic fume extraction, fume extraction systems, LEV arms, filler metals, and the advantages and disadvantages of each -

Regulatory Requirements

Legal considerations with a focus on the United States and Canada -

Fume Extraction: Frequently Asked Questions

The most common questions we get all the time answered -

Conclusion

Final thoughts on fume extraction -

Contact Us

Speak with a fume extraction expert to find the right fit for your operation

About the Authors

Etienne Blouin is Director of Environmental Health Systems for ABICOR BINZEL USA. Etienne has worked on implementing fume extraction welding solutions for ABICOR BINZEL for 8 years, working directly with end-users to identify optimal fume extraction measures for their welding operations. Etienne is a graduate of Université Laval with a degree in Physics Engineering.

André Faber is Head of Extraction Technology for ABICOR BINZEL. He is working in the welding industry since 2004, first as a construction engineering and then as a product manager for manual products at ABICOR BINZEL. André is a graduate of TH Mittelhessen University of Applied Sciences with a diploma degree in Mechanical Engineering.

So you’re thinking about making the change to fume extraction? That’s great! Your welders will appreciate it as will the rest of your employees.

Fume extraction – especially at the source – has been one of the more interesting and health conscience welding concepts to come around in quite a while, and with occupational health and safety only becoming more demanding from governing bodies around the world, you might want to get ahead the curve as much as you can while protecting your workforce at the same time.

What Fume Extraction Welding Is

Fume extraction is the removal of fumes – either via welding, cutting, or grinding, from the work area to keep them from being inhaled by workers. The most common generation and extraction of fumes comes from welding as a result of the process – gas and current mix with a filler metal to produce fumes at the arc.

Some fumes are very visible, others less so – even if they are there. Factors like welding parameters, wire, gas, and base material all impact the thickness and prevalence of fumes in the weld shop.

No matter how visible fumes are, they are definitely being generated and your workers are being exposed to it.

Why Fume Extraction Is For You

In truth, fume extraction is for anybody doing welding in any way, shape, or form. Whether you are just learning the trade in a school, running a small shop doing repair work, or run a large scale fabrication outfit, fume extraction solutions large and small, simple and complex, exist to remove weld fumes from the worker environment.

Fume extraction isn’t just a workplace environment benefit, it also is protecting your workers and company from serious health risks. A 2019 cohort analysis study in Occupational and Environmental Medicine looked at over 17 million welders worldwide from Germany to France to the United States and found that welders and people exposed to welding fumes were 43 percent more likely to develop lung cancer.

With risks like that becoming more apparent, and more research being done to truly grasp the effect of welding fumes on industrial workers' long-term health and safety, governments and companies now more than ever either are or will be looking at fume extraction as mandatory methods of protecting the workforce.

When it comes to fume extraction, there is a lot of taboo and bad information. In truth, it’s really a lot easier and more cost-effective to introduce fume extraction into your plant than you think. And, what’s better, you won’t sacrifice performance to get there.

This guide is going to walk you through exactly what you should be aware of and will want to know as you look at fume extraction for your welding operation.

Lots of people worry that integrating fume extraction into their welding operation will negatively impact it. That’s not the case. You will find as you talk with people who have started to use fume extraction in their plants that they haven’t had to alter any of their current welding procedures or weld positions to accommodate it. The things that do impact your decision have more to do with what you weld than how you do it.

What metals are you currently welding? Does it matter?

Yes, the metal being welded does matter. All metals release different contaminants to the air as you weld.

Stainless Steel

Metals like stainless steel – which contain steel iron, chrome, nickel, and manganese, are extremely hazardous welding fumes for your welders to breathe in. You may need to get a specialized fume extraction system to safely collect and dispose of those kinds of contaminants.

Hexavalent Chrome

Anything involving chrome or nickel extraction should be IFA-W3 certified.* Hexavalent chrome is the most harmful particle released into the atmosphere when you are welding, with a +6 valence state. It’s present in all stainless steel and is a known cause of cancer per several standards, studies, and findings. Having a W3 licensed extraction system that can remove these harmful elements when the CrNi content is above 30% is a very important consideration.

Galvanized Steel

Galvanized steel also is a dangerous metal for welders to intake and is another metal that is a great fit for fume extraction because of the harmful fumes released. In galvanized steel, the alloyed properties creating that metal include iron and steel with a zinc coating.

When zinc is welded, for instance, it releases zinc oxide fumes, which like exposure to manganese, copper, or beryllium, can cause fume metal fever, which damages the respiratory system. Other metals like lead, which can be used like zinc as a coating on certain metals, can even damage your central nervous system.

Aluminum

Another common welding metal – aluminum – is less a fit for fume extraction MIG torches and collection systems than some of the harder metals out there. The reason being is the process involved.

While still creating a lot of smoke at the arc, aluminum oxide fumes are considered less hazardous as they are not as toxic as manganese, chromium, or nickel, and the health effects are more irritant in nature than chronic or long term. Plus, with the softer property of aluminum, using Push-Pull MIG guns or Spool Guns – which because of the sophisticated wire feeding system cannot accommodate a fume extraction cable or shroud – is necessary.

Do You Have to Change Your Current Welding Setup for Fume Extraction?

Fortunately for you, the answer is no! You can use the same procedures and protocols, and systems you were previously using in your MIG welding operation and seamlessly integrate fume extraction into it.

A general rule to follow is the higher the amperage used the more you will release welding fumes into the welder atmosphere. Likewise, some welding processes create more fumes than others.

Do you have to buy new equipment for fume extraction?

Yes. But that doesn’t mean the welding parameters or setup is changed. You would have to look into purchasing a vacuum system and a smoke extraction gun to make the full commitment and develop an engineered solution, as is typically recommended. Otherwise, there’s no change to the way you currently weld that you’ll have to do other than introduce and use the right equipment for capturing those harmful welding particles.

If fume extraction at the source is not a viable option with a fume extraction torch, fume extraction arms are another source capture route to go that will improve air quality for your welders and staff. As a complementary piece to an extraction arm, respiratory masks can give additional coverage and protection for your welder. Ideally, however, you want to take action as close as possible to the source to prevent weld fumes from spreading. The more localized, the better. As localized fume extraction solutions become less feasible, more general solutions become possible.

Respirator Masks

When choosing a respiratory mask, at least in the United States, it must be approved by the National Institute for Occupational Health and Safety (NIOSH). Typically, when dealing with welding fumes, you will consider either half-mask respirators, powered-air-purifying respirators (PAPR), and supplied-air respirators (SAR). When using these types of masks, remember that cartridges and filters have to match the contaminant it is protecting against and be changed periodically.

Respirators also are typically last resort solutions and should be used when engineering control systems – like ventilation control through fume extraction torches and systems, are not feasible, per the Centers for Disease Control. Reason being is while they may be more cost-effective alternatives to combat welding fumes, they are best utilized in combination with an engineered solution and not as the sole means of protection against hazardous fumes.

Test Fitting for Your Respirator Mask

When using a respiratory mask, consider fit-testing to ensure the snuggest fit possible, and checking to make sure your welding doesn’t have any heart or lung conditions that could make wearing a respirator dangerous. OSHA, in fact, has a mandatory medical evaluation questionnaire for OSHA Respirators, so make sure your welding operators complete this before fitting them with a mask.

Is Fume Extraction Really that Much of a Health and Safety Improvement?

Absolutely. The health improvement using fume extraction is undeniable. One study from the University of North Carolina found manganese concentrations reduced by up to 50%, so the health improvement for the welder can be quite significant. Even the most modest of results in this study showed a 20% reduction in manganese concentration.

Results are always dependent on the metal involved, the welder position, and the weld in question (whether it’s inside, outside, in an enclosed space, etc.).

How much of an improvement will always depend on the equipment investment made and the types of metals welded. It also depends on placement – where the fume extraction system is placed relative to where the welder breathes.

Often times this is done in error, and fume extraction as a result is not as effective as it otherwise could be because the welder is positioned in the plume.

III. Fume Extraction Welding Solutions

First, let’s reiterate that no matter the fume extraction system you choose, you don’t have to change your welding procedure or welding machine. The only change you will be making is using a new welding gun and utilizing a fume extraction system – whether centrally located or portable/mobile – to have fume extraction in your operation should you decide on a source capture solution.

The welding positions your welders currently perform won’t change and the welding procedures you currently have in place will not need to be altered just because you’re using fume extraction. It’s a very common concern among those considering the switch, but we can tell you from our years of introducing fume extraction solutions to a variety of end-users that none of them have had to change their positions or their operations to accommodate it.

Here we will cover each of the options you have at your disposal for fume extraction, their pros and cons, and what considerations you should make for each.

Fume Extraction Guns (Source Capture)

Fume extraction guns look and feel bigger than normal MIG guns because of the design. First, there’s the hose that’s needed to extract the smoke. Second, the nozzle and the fume shroud on the front end can give a bulkier handle than normal MIG guns. This tends to turn off welders at first glance, but chances are there is a fume gun that meets your welders’ demands.

Research the market to find the best guns available. Some have smaller nozzles, smaller grips, better ergonomics, work well in corners and hard to access areas, etc. Some are also lighter in weight. Weight is a huge factor in considering fume guns.

You want to make sure the gun you select has three things going for it:

- The gun is going to be as light and comfortable as possible

- The gun extracts smoke properly

- The gun allows the welder to access the same welding positions as before

Welder Access

For welder access, typically the feature for a fume extraction gun to evaluate most closely is the torch neck angle. The better and more natural position the welder is able to take, the more comfortable he or she will be and the more smoke will be captured.

When evaluating fume guns, the most effective torch neck angle from our years of on-site evaluation is a 60-degree torch neck. Anything lower – such as a 50-degree angle – will cause the welder to have to lift the torch unnaturally to capture smoke effectively – reducing their job performance and the performance of the fume gun.

>>>Blog Article: 4 Problems with Fume Extraction Guns and How to Solve Them

Torch Ergonomics & Weight

Comfort is such a big consideration to make because the effectiveness of fume guns will ultimately be reliant on the welders’ willingness to embrace them as the tool of choice. That’s not always an easy sell, but MIG gun manufacturers have gone to great lengths to add more comfort and reduce weight and stress on fume extraction torches without compromising performance. Some of these improvements include ergonomic handles and swivel designs on the cable for freer wrist movement. The idea behind this is to make fume guns easier to maneuver.

Typically fume guns used to be heavy because of the cable weight and the handle design. Research to find one's most comfortable for your welders. There are several fume guns on the market that are just as light and easy to handle as standard MIG guns.

Fume Shroud Design

Shroud design and placement in relation to the nozzle is also a very evaluation feature for fume extraction guns. The shroud is what gives the fume gun the ability to capture smoke, and is where the vacuum system is suctioning from on the welding gun.

Shroud position is important because a shroud that is too close to the process can cause porosity from causing gas turbulence, while a shroud too far removed from the process won't capture smoke effectively.

The shroud openings are another consideration to make. Larger shroud openings and shrouds with enveloping design - think of umbrellas - are very effective shroud designs for capturing weld fumes without causing turbulence in the gas column.

Fume Extraction Hose Design & Flow

A fume guns’ ability to capture fumes effectively is very dependent on the hose design of the fume gun. This includes the hose diameter and limiting the restrictions inside the hose to allow smoke to move freely from the shroud to the extraction system. Ideally, all fume guns would have very large hoses that would leave no air restrictions and allows smoke to pass through easily.

But that involves comfort tradeoffs on the welder ergonomics, so there is a compromise between the two. The typical hose diameter you will see in the industry will be 1.25 inches (32 mm), with some makers going as high as 1.75 inches (44 mm) to try and improve flow. From our experience, any house diameter beyond 1.5 inches will typically be too cumbersome on the welder to use on a consistent basis.

The flow through a fume extraction welding gun is measured and applied by connecting vacuum pressure on the back-end connector of the torch and putting as much airflow through the fume gun front end as possible. The big debate among fume extraction users who utilize a welding solution is: how much flow do the fume gun and vacuum system need? The answer to that is as much flow as possible without compromising the process – mainly the shielding gas. This goes back to the earlier evaluation criteria of shroud design and placement – for example, the closer the shroud is to the process, the less flow it will be able to take because if too much air is being suctioned that close to the process, then shielding gas will be captured by the fume gun and cause weld porosity.

Welding Torch Consumables – Where the Value Is

Also, look at your consumables. The better the consumable, the more value you will get out of the torch. Consumables with a tapered front end, for instance, would always be preferable because of the ease of maintenance and improved access.

You also will experience less spatter build up because coarse threading resists binding and stays concentric with the tip holder. Look for the quality of the consumable. Copper, chrome, silver, and nickel all are considered high-grade consumable materials.

And the more malleable the metal the better the performance.

How Do You Test a Fume Extraction Gun Against Your Current MIG Gun?

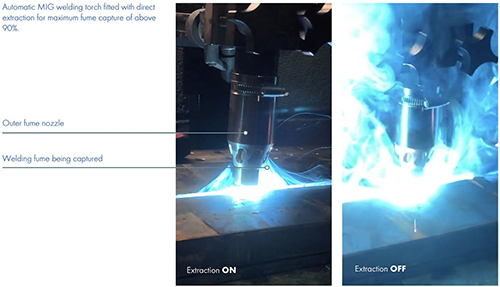

We recommend a simple comparison test. Take a normal MIG torch and weld regularly to see the current level of smoke being emitted. Then, try the fume gun in the same position welding the same piece and make sure it can do what you want. If you want to try out different fume guns, go for it! Then, choose the one that extracts the smoke better. You’ll be able to literally see the difference, as the better fume extraction MIG guns remove the fumes right at the arc.

Robotic Welding Fume Extraction

Health hazards created by welding fumes and the associated safety problems of affected workers can also be prevented in automated welding processes – notably robotics. With welding fume extraction in robotic welding, there are several methods available for manufacturers looking for comprehensive solutions.

Conventional Robotic Fume Extraction Applications

Conventionally, the use of fume extraction in a robotic application involves some method of enclosing the robotic weld cell, configuring some sort of ducting grid, and exhausting weld fumes to a collector unit within or outside the plant.

For manufacturers who weld large customized parts or need to use an overhead crane in order to lift out parts, these methods aren’t possible and normally the best option is to utilize fume extraction solutions that recirculate air throughout the plant. While this is possible and sometimes seen as an acceptable solution, weld fumes still are passed through the plant and workers are exposed with little means of avoiding it.

All of these solutions are likewise significant plant upgrades in order to accommodate. Significant investments in air filtration equipment and ducting plus a possible reorganization of the shop floor is required to accommodate a fume extraction retrofit of such magnitude. Unsurprisingly, not all manufacturers can afford the amount of retrofitting, downtime, and plant equipment all at the same time.

Source Capture Robotic Fume Extraction

However, other such solutions do exist. For instance, the use of a single fume extraction unit can cover several workplaces and ensure protection against welding fumes for several workers. When possible, the fume extraction should be directly at the source during welding. By extracting the welding fumes immediately during the welding process, there is no possibility of the welding fumes rising and damaging the health of the workers in the plant.

An extraction system consisting of an extraction kit attached to the robot torch and connected to an extraction unit collects the welding fumes with such an enormous vacuum that no harmful gases can escape.

One of the notable differences from robotic fume extraction to manual fume extraction for source capture is that the static pressure requirements are far different. The reason being is there are far fewer obstructions within a robotic fume extraction setup compared to a manual.

With manual welding fume extraction, machined parts, cables, hoses, and fittings all work to restrict the flow of smoke from the neck of the welding torch to the back end connect into the extractor unit.

With robotics, you are installing an extraction kit separate from the welding torch cable, meaning there are no obstructions that restrict the flow of smoke to the extraction unit. This means that while with manual welding for fume extraction it is necessary to pull at least 50 inches of water column in order to adequately capture the smoke, for robotic fume extraction as little as 20 inches of water column can collect >95% of the weld smoke at the source and save your workers from having to inhale weld fumes.

Source Capture Robotic Fume Extraction Advantages

The clear advantage for an at the source robotic fume extraction solution is that the system is a lot smaller, a lot less expensive to build, and a lot less cumbersome. With an extraction unit at the source, you don’t need a big cage around it, which allows not only for a significant amount of cost savings but also for the system to be a lot more flexible, especially when welding big parts.

In robot cells, longer distance gaps often have to be bridged. Several robot torches, each equipped with an extraction kit, can be connected to a centrally located fume extraction system. This method is perfect for reliable, accessible, and safe extraction during MIG welding at several workplaces. This type of fume extraction is used, for example, in the general manufacturing, heavy mechanical engineering, construction, and industrial energy applications.

Just as in manual welding, fume extraction does not disturb the welding process in a robotic welding area. In certain positions, it can happen that when welding fumes are extracted, shielding gas is also extracted from the welding process. In the worst case, this can mean porosity in the welding seam. To prevent this, the extraction performance must be adjusted. Especially in the case of direct extraction, the reduction of the extraction power is the only way to avoid pores in the welding seam.

Robotic Fume Extraction: Low Vacuum vs. High Vacuum Extraction Systems

Low and high vacuum systems are terms that are used often when you are consulted on fume extraction possibilities. In a robotic setting, it’s important to know the differences between the two and what one offers over the other.

Low vacuum and high vacuum systems refer specifically to static pressure. If you are able to install large ducts, you can take the traditional route with a big blower that will extract thousands of cubic meters (or feet) of air through the hood. The advantage of this is because you are using a low static pressure – i.e. low vacuum – the systems are closer to what people have traditionally been familiar with through mechanically engineered HVAC systems, vacuum systems, etc.

What it means in terms of fume extraction for welding is that you need high volumes of air to be moved, and needing to throw the air outside means incurring an expense to take hot air in the winter and move it.

If you need to bring cold air back in the plant during the summer, there’s likewise a cost to condition air back into the plant to make up for the same amount of air you are extracting out of the plant area. The air circulated back into the plant needs to not only be fresh air but also conditioned to a thermostat setting. The cost of moving such high volumes of air, as expected, can be high month over month.

A high vacuum system uses less flow at higher vacuum pressure. Because the static pressure and velocity of air are higher, you don’t need a big hood or arm to use a high vacuum system. Typically, you will be closer to the source of the smoke with high static pressure as opposed to ventilating a large hood with a low vacuum.

This allows for smaller devices focused on where the smoke is created as opposed to large devices. With low vacuum fume extraction solutions in an industrial welding automation setting, you are using large systems positioned further away from the arc and extracting the contaminant mixed with the air. As a result, you have to use more air and use more volume to remove welding fumes as opposed to addressing the most contaminated location of the process.

Source Capture Filter Cleaning & General Maintenance for Robotic Fume

Welding fume and the gases contained must be filtered so that nothing harmful ends up in the air. In robotic welding, these filters should be able to clean themselves. In an automatic cleaning process, the pressure difference between the clean air side and the dirty air side is measured. If there is a pressure difference, an impulse comes and compressed air is blown in to clean the filter.

In an ideal world, this process run would happen while the vacuum system is still in operation extracting fumes from an active robot cell. This is a great advantage as there is no downtime due to cleaning times for the filter.

In addition to the automatic cleaning of the filter, there are other maintenance and cleaning tasks that have to be performed manually. The extraction nozzle and the hoses should be cleaned regularly so that they do not clog. The dust drawers must also be kept clean and the carbon brushes must not be worn.

Source Capture Robotic Fume Extraction Challenges

That doesn’t mean robotic fume extraction at the source is not without challenges. Mounting an extraction kit to a robot presents it’s own set of unique challenges. Making efficient use of the mounting provision for a 6-axis robot while allowing for the extraction hose to rotate and move in relation to the cable is critical for effective fume extraction that doesn’t fail constantly. Being certain the extraction hose is optimally positioned to capture the smoke is another key consideration.

Like with manual fume extraction, the design of the shroud fittings must lend themselves to capture the smoke without interrupting the process. Ensuring the extraction kits avoid causing unnecessary robot crashes and give the robot torch front end access to the part are other critical factors to consider when looking at robotic fume extraction at the source.

Source Capture Robotic Fume Extraction Considerations

If the health of the workers is a priority and if you are interested in welding fume extraction for robotic welding, the most important key data you should request for information is the dimensions and characteristics of the equipment, the electrical data, the performance, and the filters used.

With this information, it is possible to connect your own welding process with the possibilities of robotic fume extraction. The installation of a fume extraction unit is relatively simple and quick and does not take much longer than 1-2 hours.

Mechanized Fume Extraction for Hard Automation

Mechanized welding systems are used in simple automation processes where it is possible to apply repeatability mainly in plate, beam or pipe welding. These systems seek to reproduce the operations performed in manual welding situations.

Mechanized systems require less equipment investment over robotic processes and are widely used in more open areas rather than closed cells. Tractors or stationary systems are used for welding joints. Another use is the application of welding on large workpieces.

In mechanized welding, the welder manipulates the equipment or torch for adjustments, control and visual monitoring of welding.

In automatic welding, the welder/operator is exposed to welding fumes and the use of personal protection is mandatory. Even if the environment is well ventilated, fume exhaustion is recommended, as in these actions the exposure of the welder is direct in addition to the passive exposure by people passing through the environment where the welding is being performed.

Mechanized Fume Extraction Practical Application

Collecting fumes through exhaust arms with hood systems is used in processes where the torch remains in a static position or performs short movements.

Direct torch extraction systems are also used in the mechanized process and have greater extraction efficiency as they act directly on the front of the torch close welding with efficiency above 90%, performing smoke aspiration before dispersion in the environment.

Mechanized Fume Extraction Considerations

It is important to consider clearance issues with extraction systems that are mounted onto the welding torch as opposed to being part of the tool itself. As these systems are part of the torch neck, considerations like tractor or gantry speed, for instance, don’t carry much influence on the effectiveness of smoke capture.

When using a source capture solution for a mechanized or hard automation process, you usually want to have the torch angled somewhere between 0 (or 180) and 30 degrees to optimally capture the weld smoke.

Fume Extraction Systems – Central & Portable

To do smoke extraction at the source with a MIG gun for manual or robotic source capture applications requires a high vacuum system. Whether it’s portable or central or mobile, if it isn’t a high vacuum, it’s not going to effectively collect welding particles and you’ll still be subject to the same amount of health risk as before.

When we say high vacuum systems for fume extraction welding, we mean high static pressure with low flow, and that is in contrast to fume extraction arms, where you’ll be looking for an arm that produces very high flow with low static pressure.

How Much Power Do You Need?

The most important thing to remember when looking at a fume extraction system is you will need to achieve a minimum amount of power from the system in order to effectively capture welding smoke. You can have more than the minimum up until the moment the fume gun begins to extract shielding gas. Fifty (50) inches of water column (12.4 kilopascal) should be a minimum baseline for your manual fume extraction systems regardless of which type of solution you choose, and the aim should be anywhere in the 80-90 range (20 – 22 kilopascal).

Are Portable or Central Systems Better?

The choice of a portable or central or whatever depends on need. If you have a stationary welding system, you can use a portable or singular unit. However, if you have more than one station, a central vacuum or multi-gun station is best. The central vacuum system is easier for the welder to connect to and it is easier to maintain.

Portable Fume Extraction Systems

Portable fume collections systems are good and generally less cost if you want to install it yourself and need to move to different locations to perform welds while still needing to maintain fume extraction. However, maintenance is more frequent as a result. This is because portable systems will have their own filter and motor which is usually smaller.

Also, because it is portable it’s more susceptible to damage – being dropped, being hit, as well as just suffering the normal wear and tear of being picked up and let down while being transported. Noise is also a downside, as the source of fume collection is right next to the welder.

>>>Blog Article: How to Test Your Fume Extraction System

Multi-Torch Fume Extraction Systems

Multi-gun unit fume extractor systems represent a kind of go-between.They’ll have a lower investment than a centralized system while behaving more like a central system in terms of performance. However, they act as a single gun portable unit in other ways.

For instance, there will be filter cleanings and replacements as part of owned stand-alone multi-gun units, and also depending on the number of manifolds the unit has there will be performance trade-offs.

Too many guns attached to the unit could mean not enough power from the extractor system, and sometimes there will be the risk of too much performance from the extractor unit, so it will suck shielding gas from the fume gun and cause porosity.

Central Fume Extraction Systems

Stationary is in many ways maintenance-free for the welder and is more a plant manager's responsibility. The welder gets to spend more time welding. Performance is more reliable and stable. Central fume collection stations almost always come with a larger motor and filter so there is less filter changing – just plug the fume extraction gun to the central system and weld. For the welder, there’s typically more convenience with central systems.

Central systems have an unlimited capacity as well – there’s no limit to the size of a central system. If you have a large plant operation with 40 or more handhelds arcs, you can get a system that can accommodate that if you want to go totally to fume extraction. There’s also less noise for the welder because the vacuum is located at a distance.

In terms of downside, the initial investment can be very expensive. But, bear in mind that central vacuums require a lot of upfront capital because of the electrical requirements, the labor involved in getting it up and running, and the consultation required to introduce a central vacuum into your plant. However, after the upfront costs, it’s a far less costly option to maintain. You won’t find yourself replacing filters or cleaning them at nearly the rate you would with a portable system, and because it’s fixed to a stationary location, your general maintenance is significantly reduced. Central systems also tend to age well.

Many of the options out there will last decades if not longer with minimal maintenance needs.

LEV Systems / Fume Extraction Arms

Local welding fume extraction with fixed or movable extraction hoods and arms can be an easy and inexpensive introduction to fume extraction system. The health of the welders can be protected with just a small investment for a local extraction solution.

How Much Fume Extraction Can LEV Arms Produce?

If the welding fume extraction hoods are correctly positioned, they can extract up to 100% of the welding fumes. However, that doesn’t mean the welder isn’t exposed to the welding fumes while welding. While the hood may be able to capture a very high percentage, the hood can’t always be placed between the welder and the process.

On average given welder habits, you can expect 70% extraction of welding fumes using an introductory system such as an LEV arm. With local extraction the possibility remains that welding fumes linger in a plant and workers are still exposed.

Source Capture vs. Localized Ventilation: The Trade-offs

Fume extraction arms are good examples of the tradeoff between performance and health benefits. Fume extraction arms are effective when they are positioned properly, but for them to work as effectively as the can, the hood has to be close to the weld and the welder cannot place themselves between the hood and the weld. In theory, it’s easy to use, but in practice, it’s very common to see the welder between the arc and the hood breathing in the fumes before the hood captures it.

There is a difference in percentage capture in a practical sense as well when it comes to fume extraction arms compared to source capture extraction. For instance, say you have a hood system and a source capture system and both capture around 90% of the weld fumes.

Even with an identical rate of capture, these two scenarios are not the same, because in reality with extraction arms the smoke is still traveling through the welder’s breathing zone on it’s way to the arm vent unless both the welder and the extraction arm hood vent is in the proper place at all times.

Why does this happen? When the weld is large or the piece is long, the hood needs to be constantly moved closer the weld where the arc is, and has to be brought into the proper position by the welder. More often than not, the welder doesn’t stop the weld to continually reposition the arm as the arc moves because it’s not time efficient.

Fume extraction MIG guns normally work better in such a scenario. They are always at the source of the smoke because they are part of the same tool. It’s part of the welding process where the weld is occurring, and also is always sitting between the weld and the welder, so it’s capturing more fumes.

Fume Extraction Arm Positioning

If the hood is properly positioned and the welder uses perfect habits or is welding on a workbench, you will capture most of the smoke – more than 90% is achievable in such an ideal scenario.

The challenge is the positioning of the flex arm as you do the job. The hood has to be in close range of the arc to capture properly. And that’s the biggest challenge of that technology.

>>>Blog Article: How Do Fume Extraction Systems Work?

Fume Extraction Arm Advantages

As an extraction solution for beginners or as an entry-level solution, extraction hoods are great because of the low price and simple use. The local welding fume extraction solutions are effective without changing anything in the welding process or working environment. The air quality is improved and the welding torches previously used can still be used.

A single extraction hood can also be used to extract welding fumes from several welding processes. You are flexible because there is no regulation of a fixed distance between the extraction hood and the weld. The extraction hood can therefore be positioned to suit the working environment.

A special feature of the extraction hoods and arms is that they can also be used for other welding processes like TIG or Plasma cutting. TIG welding is a very clean process in which only some gases are produced. If even these few gases should be arise, an extraction hood is perfect, since other extraction solutions are rarely offered for TIG and would also not be cost-effective.

Extraction Arm Filters

The extraction hoods also contain filters. For the local welding fume extraction with extraction hoods, these filters have to be cleaned. If the welding fumes are no longer extracted and remain in the working hall, the filter cartridges should be cleaned. If the filters are checked regularly, this can be avoided.

A grid in front of the extraction hood can prevent other things out of the environment from being sucked in other than the welding fumes.

If you use a light-duty process you can use filters and cartridges that are not cleanable.

If you have a high-duty process where you weld many hours a day you’d want a filter that is cleanable so that you actually can work longer without changing the filter and a filter that is more efficient for a longer time.

Extraction Arm Drawbacks & Considerations

With fume extraction hoods, one major drawback for these units is the filter size is typically very small compared to at the source solutions. Another is the quality of their build. It’s not uncommon to see extraction arm units with housing that is plastic in make. This is typically a bad sign for a portable unit because they lack the same durability as a steel constructed unit and also don’t do as well with limiting noise in the shop.

Arm mount position is similarly important. Think about the flexibility you would want to position an extraction hood. The more reach an arm is able to achieve, the better the welder will be able to position the hood vent to the correct spot. In a real-world application with larger, longer parts this still becomes difficult to execute because you depend on the welders to move the hood vent with them as they weld the part.

Suction Distance & Power

Suction distance is another feature and potential drawback for fume extraction hoods. Suction distance allows for the hood vent to be positioned farther away from the welder while still allowing it to properly remove weld fumes.

Most portable fume extraction hoods struggle to reach beyond 900 CFM (1500 m3/h). Ideally, you would want to power of the motor and blower to exceed 1000 CFM (2000 m3/h) in order to work effectively. An arm positioned too close to the welder limits the welder’s access to the weld and produces poor welder habits that will unnecessary expose them to weld smoke.

Lastly, make sure the fume extraction arm is properly specified to adequately reach the weld and that they filter is the right one for your process. These are the two biggest considerations to make when evaluating an LEV extraction system for your process.

Fume Extraction for TIG Welding

TIG welding produces the least amount of harmful fumes compared to other forms of manual arc welding as shown in the graph below. That said, it does produce significant amounts of ozone and nitrous oxide both of which are irritant gases. Ozone is a particular cause of dryness of the throat, tickling, coughing or a tight chest especially when TIG welding stainless steels and aluminum.

Welding Stainless Steel with TIG

The harmful fumes created when welding stainless steel is believed to have serious effects on the health of welders and people in the welding environment. Chrome & nickel fume is highly toxic and can damage the eyes, skin, nose, throat, and lungs and is carcinogenic. Because of the hazardous substances that develop during the welding of aluminum materials, protective measures must be taken.

So, what are the options?

Fume Extraction Options for TIG

Unlike MIG welding guns, on-torch extraction isn’t currently available for TIG torches. Other forms of extraction have to be used when welding high volume production with TIG, especially on stainless steel or aluminum parts. The current forms of fume extraction available when welding with TIG are:

- Magnetic Fume Nozzles

- Extraction arms/hoods (LEV Systems)

>>>Blog Article: Fume Extraction Units - Telling a Good One from the Rest

Magnetic Fume Nozzles

These are ideal for TIG welding especially for bench work where you aren‘t moving down long weld runs. With its funnel style extraction opening (round or fish-tail) and magnetic mounting stand, it gives the welder a great amount of flexibility as he or she is able to position the nozzle directly over their weld. These types of nozzles can be easilly connected to a portable fume extraction unit via an external extraction hose (see illustration).

This setup is a very cost-effective solution to removing those harmful welding fumes while TIG welding.

Extraction arms/hoods (LEV systems)

Where companies that are welding stainless steel have adequate exposure controls available, a lot of the time these controls are not used or are used incorrectly. Reasons for this include a reluctance to regularly reposition the LEV hood as the job progresses (welding long beams) and also a common misconception that LEV can affect the weld quality such that LEV is not used or positioned so far away from the weld that it is not effective.

In the UK, for example, it is recommended that LEV hoods be at least 6 inches above the weld for it to effectively remove welding fumes. But some countries don’t have such recommendations or best practices. If in doubt, consult an industrial hygienist or your company’s Safety Officer.

They can be used flexibly at almost any manual welding workstation and for all welding, cutting and grinding applications. The extraction unit is also suitable for particularly cramped and hard-to-reach areas with poor lighting conditions and tasks where a standard welding torch without extraction is required.

Is there a National Law to follow? A local?

In Canada, the current occupational exposure limits are determined by province. So, what the limits are for Ontario may not be what the limits are for Quebec. Looking at Ontario, for example, the Ministry of Labour provides a table to use as a guide for exposure limits, and employers must take reasonable measures to protect workers from these substances. Chromium metal compounds, for instance, have a time-weighted average limit (TWA) of 0.5 mg/m3, with that TWA being 8 hours.

OSHA in the United States has several Safety and Health Regulations for welding and cutting when it involves certain types of metals or welding with certain types of gases. For instance, when welding or cutting zinc-bearing base or filler metals with zinc materials, lead base metals, cadmium bearing filler metals, or chromium bearing metals, it is mandatory that a general mechanical or local exhaust ventilation system be used that keeps welding fumes and smoke within safe limits.

If the metal contains beryllium, for instance, welding would have to be performed with both a local fume extraction system and with an air-line respirator. OSHA has several guidelines for welding with certain metals and gases, and we highly recommend checking their website to see what fume extraction equipment you may need to have based on what you’re welding.

Every country and even region may have it´s own regulations and standards when it comes to exposure limits or mandatory equipment. As we cannot provide a full overview about every regulation in every country, it is important to check for yourself if there are national or local requirements you need to follow before deciding about a fume extraction solution.

What are some of the best practices for fume extraction welding?

If you can extract the welding fume right at the source, it’s always better than any other method. The intent always is to make sure that the manganese or zinc oxide or hexavalent chromium doesn’t spread throughout the plant and become inhaled. Think of it as a virus and you’re trying to cover up a cough or a sneeze. If you can control the smoke right at the arc and get it at the source, it’s best.

You also have to protect your welder as well as others in the general area of the welder. Remember to always wear proper personal protective equipment. For instance, wearing a respiratory mask is one way to provide an additional barrier of protection for your welder to make sure he or she isn’t ingesting smoke fumes. If you aren’t removing the fumes at the source, it’s highly recommended if not required in your area that your welder is wearing some kind of mask to protect against breathing in fumes on top of wearing eye protection.

There are also ventilator cells that filter fresh air into the welding mask to directly provide clean air for the welder to breathe while they work. If you consider this route, keep in mind that there are different respiratory masks and filters for different types of metal.

Where can I get more information on how to make sure I’m compliant?

You should refer to your local Occupational Safety office. In Canada, for instance, every province is responsible for their own occupational safety standards, so what’s accepted in Ontario may not be proper in Quebec. In the United States, the standards are nationally recognized by OSHA, so refer to OSHA.gov for more information.

Also, if you have a Safety Officer in-house, consult them, as they should be up to date on what you need to do to be compliant. Reach out to a Certified Industrial Hygienist who can assess your welder’s air quality and help determine the right course of action for you.

What Should You Be Looking for When Considering Fume Extraction Solutions?

There are lots of options out there. The right one will depend on your needs. Here we’re going to go over what you should be looking for when making that important equipment decision.

There’s usually a question of whether all that additional design and engineering that goes into these fume guns affect the performance of the gun itself.

Is there a loss of amperage? Will it fatigue my welder more? We answer those concerns below.

Am I sacrificing performance for safety?

While it is argued that fume guns don’t ‘perform’ as well, the answer is no, you won’t sacrifice any performance. Today’s fume extraction welding guns perform just as well as regular welding guns with capacities from 200 to 500 amp air and water-cooled for almost every possible situation a standard MIG gun handles. The guns also feature the same range of features as in a standard MIG gun.

Is it more strenuous on my welders even if it’s healthier?

This is a great question because there are fume extraction guns that can be heavy and bulky to handle, which can affect welders’ stamina. But, even the strain of using a fume extraction torch would depend on the gun you’re changing from and the smoke gun you’re picking, because there are fume guns out there that achieve the same feel and handle as most MIG guns on the market.

It’s also a matter of welding positions. Overhead and vertical welds by their very nature are more straining weld positions than horizontal or down welds, so heavier fume extraction guns could be more strenuous and adversely affect performance because if the welding gun isn’t positioned properly it won’t capture the fume as much as it could.

However, these concerns and the guns’ performance again depends on the MIG gun being switched from and the fume gun in question. Take a demo and see if the difference is real.

You can find plenty of MIG guns out there with the swivel at the base of the cable, and there are plenty of cables out there that weigh the same as many non-fume extracting MIG torches on the market. Do your research and talk to your welding supplier or a qualified rep.

Are fume extraction guns heavy?

This was a common issue with the first generation of fume extraction guns. In order to fit all the additional components into the first fume extraction guns, there was a significant amount of added weight that made the gun bulky, heavy, and cumbersome to handle.

Today, with a much-increased focus on weight reduction, welder access, and torch ergonomics, modern fume guns are far more comfortable and welder-friendly tools. So much so, that some fume guns, including our own xFUME™ / RAB torch line, are actually less in weight than comparably rated, non-fume extraction MIG guns. Weld.com has a great YouTube video that covers the fume extraction weight question.

Do fume extraction guns use different consumables?

The only additional consumable a fume extraction gun requires is the fume shroud.

Other than that, you’re using the same setup as a regular MIG welding gun: diffuser, tip holder, contact tip, and nozzle.

Consumables such as the diffuser, tip holder, and contact tip are the exact same for regular BINZEL MIG welding gun as our fume extraction torches (nozzle may vary depending on fume extraction gun model). And for most other manufacturers it is also the same.

Do fume guns capture the welding gas?

Fume guns have been really sensitive to creating porosity from the vacuum sucking up the shielding gas and replacing the gas with oxygen. This in the past has caused a lot of bad welds and a lot of reworking which undercuts the investment into fume extraction guns and extractor systems.

You want to make sure all the vacuum you apply is not reaching the zone where the shielding gas should be. If you measure turbulence near the end of the shielding nozzle, then your flow is too strong or your shroud too close the welding operation.

Do fume extraction guns connect to my welding machine?

If you use an industrial welding machine, such as a Millermatic® or a Lincoln® Power Mig® or a welding machine of similar amperage rating and capacity a fume extraction torch is easily configurable for such a machine. Any Euro-style machine can also be easily fitted to a fume extraction torch.

The only types of machines that would be difficult to fit a fume extraction gun to would be a portable style or hobbyist welding machine.

If you use a fume extraction gun, you have to pair it with a fume extraction system, ideally one that is suited for your welding parameters.

How long the cable covers last on fume extraction guns? Do they catch on fire?

The durability of the outer hose varies. It ranges. But it is a special material that is resistant to heat spatter and UV. Eventually, it will need replacement like all welding cables, but it does hold up to the normal industrial environment. There are extra protection covers you can use to put over the outer hose as well to give it extra life and protection.

Are some filler metals not good fits when it comes to Fume Extraction?

In short, no. Fume extraction guns handle any wire – whether flux-cored, metal-cored, or solid wire. However, depending on the wire used there can be more smoke produced, which is a consideration and an item to evaluate as you look at all the options with fume extraction solutions. With metal-cored and solid core, you will be looking at higher parameters normally as well as hotter gas mixes, which will translate to faster traveling smoke and more difficult welding positions to do fume extraction with for a source capture solution.

Metal-cored presents one of the common misconceptions of fume extraction welding. For some, it is believed that welding metal core wire with a clean gas mix (i.e., CO2) creates a ‘clean’ smoke that doesn’t need fume extraction. This is a common myth. Toxic particles will still be released into the atmosphere from the base metal and from the wire as it melts to join into the weld joint, and without proper fume extraction equipment and procedures in place, your welders and the rest of your workers will breathe it in and be adversely affected by it.

Flux-core wire produces a very thick and visible smoke when being welded with. It also releases a lot of particulates into the atmosphere that you would want to catch at the source so as it wasn’t breathed in by your workers. Flux-core also is generally used for low parameter welding, which makes it very easy to extract at the source because lower parameter means slower smoke travel.

How long do filters last for fume extraction systems?

Filter life on fume extraction systems is tough to predict. Systems with a cleaning device will typically last between 6 to 12 months.

For systems with no automatic cleaning process, it’s very dependent on the filter size, the welding wire used, base metal, and the parameters of the welding machine.

For instance, high vacuum systems without an automatic cleaning system can need filter replacement after as little as two spools of flux-cored wire.

On LEV systems, the filter is normally not automatically monitored. This means there is no signal as to whether the filter is full or not.

How long the filter lasts depends on the duty cycle, the welding process, the material welded, etc.

As a rough calculation, if you’re using a fume extraction arm 3-4 hours a day the filter has to be changed one time per month.

Regardless, it’s important to monitor the efficiency of the fume extraction system. If you find it is not adequate, the filter is one of the first items to check.

Some systems have sensors or gauges built in that will activate when the differential pressure in the filter is too high, which lets you know you need to replace the filter.

Is flow adjustable for fume extraction systems?

Yes, some systems do offer adjustable or dual-flow set-up. Check with whichever company you consult with on fume extraction solutions to see if they offer it.

Fume extraction units for ABICOR BINZEL's fume extraction systems do have an adjustable flow feature.

What’s the maximum flow for fume extraction systems? What’s the right flow?

Any fume extraction arm would be in the range of 1000 – 1200 m3/h flow. Some arms go lower. These systems will ideally have higher flow and lower static pressure compared to solutions you would pair with fume extraction torches. Remember with fume extraction system flow is the key performance metric.

Portable fume extraction systems are measured on static pressure more than flow. For a portable fume extraction system, the typical range is anywhere from 50 – 100 CFM (85 - 170 m3/h).

An important item to consider is that the flow mentioned in most product catalogs assumes zero restriction, which is not a solution based in the real world. There is no good and simple answer for what your flow is going to be once you connect a fume extraction gun to the system. These results typically sit on a flow curve.

Since the torch is typically a very restrictive tool, keep in mind you will need a unit able to produce a high static pressure to overcome a torch’s restrictions.

VI. Conclusion

Today you want your workforce to be in a safer, healthier environment.

Healthier welders mean happier welders, which fosters better performance for your operation.

There have been a lot of options introduced to the market for fume extraction, and there are many ways to introduce fume extraction into your plant no matter the number of arc stations you have or the budget you’re able to dedicate towards it.

If you’re still skeptical, ask your welding supplier to provide you a demo or a trial with a fume gun in your own work environment and see if there’s a difference.

It’s no risk!

Chances are you’ll be surprised, and may look at fume extraction in a whole new light.