TIG welding robot for pipes SWR TIP TIG®

Weld with TIG quality at MIG/MAG speed

The TIG welding robot for pipes SWR TIP TIG®1 is the economical solution for precise, clean and practically defect-free weld seams with a perfect appearance. Weld seams almost 3 times faster than with manual welding and with consistent quality.

1) TIP TIG® is a registered trademark of the company TIP TIG®

Advantages of the TIG welding robot SWR TIG TIP®

- Up to 300 % higher welding speed

- Up to 60 % cost savings compared to manual TIG welding

- Consistently high-quality weld seams from the root to the cap layer

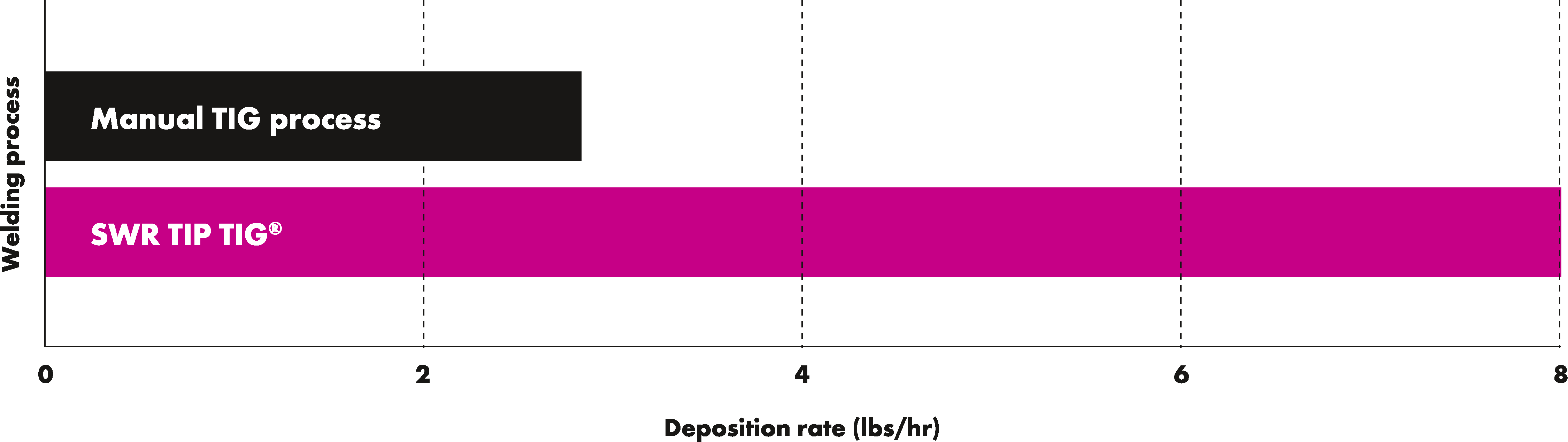

- 2.6 times higher deposition rate compared to TIG welding

- Good control of arc and weld pool

- Minimal spatter formation

- Easy to use even for welders who are not specially trained in TIG welding

You process more pipes per shift. You relieve your welding specialists. You ensure consistently high quality for every welded layer. You always have full control of the welding process. Depending on how often the SWR TIP TIG® is used, the investment is amortized after only 6 to 18 months.

2.6 times higher deposition rate

Features: What distinguishes the SWR TIP TIG®

With the TIG welding robot SWR TIP TIG® you can exceed quality standards:

Weld pipes faster, more precisely and thus more economically compared to manual TIG welding – from the root to the cap layer. You can achieve clean weld seams even with thin materials

The SWR TIP TIG® easily welds the following materials:

- Carbon steel

- Stainless steel

- Duplex steel

- Super duplex steel

- INCONEL® alloys

- Titanium

Easy integration into production processes

A TIG welding robot SWR TIP TIG® can be easily integrated into the production chain. It has a relatively small footprint of just 1.2 m x 1.2 m. The working area is over 9 m in diameter. You can operate up to 4 positioners with one SWR TIP TIG®. It couldn't be more efficient! For further details, please refer to the technical data.

Technical data

| Power requirements | 230 V / 50Hz; 240 V / 60 Hz |

| Power supply |

Lincoln Power Wave® R450 Advanced process module |

| Wire feeder |

TIP TIG® robot feeder system |

| Operating temperature range | 5–40 °C (4–104 °Fahrenheit) Temperatures outside this range may affect the function of your SWR, lead to premature failure of important components and invalidate your warranty. |

| Air supply |

|

|

Concrete floor requirements (C25) Compressive strength min. 250 kg/cm2 |

|

| SWR internet requirements | Wired internet via LAN with a minimum of 75 Mbit/s for upload/download |

| Positioner integration | Up to 4 positioners |

| Pipe diameter | 22“–60” (larger pipe diameters are possible, contact us for more information) |

| Materials | Carbon steel STD, stainless steel SCH10 & 40, 4130 (contact us for other materials) |

| Wire diameter | 0.035“ (0.8 cm) |

| Wire delivery type | Drum or spool |

| Working envelope diameter | 30 ft (9.1 m) |

| Height | |

| Footprint | 4‘ x 4‘ (1.2 m x 1.2 m) |

Manual TIG welding of pipes is time-consuming and stressful for the welder. If you want to speed up your production processes, the TIG welding robot for pipes SWR TIP TIG® is exactly the right solution. Simply integrate it into the production chain and weld high-quality seams.

Increase the precision and efficiency of your production with this TIG welding robot, which ABICOR BINZEL offers in cooperation with the Canadian company Novarc Technologies. TIG welding with the TIG welding robot SWR TIP TIG® takes your pipe production to a new level.