LASER SYSTEMS – holistic solutions from laser processing to process monitoring and quality assurance

When speed, precision and economic efficiency are required

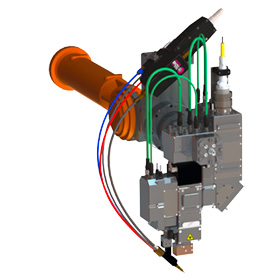

High quantities, quickly produced weld seams and the highest quality requirements - welcome to laser welding and laser brazing. Especially in the automotive industry, lasers have become indispensable. From doors and roofs in car body construction to car seats, battery cells, battery modules and stator hairpins of electric motors, laser joining processes convince everywhere with highest precision, speed and economic efficiency.

Together with strong technology partners, ABICOR BINZEL offers optimally coordinated, holistic system solutions. For laser brazing and laser welding with filler material, we will continue to rely on the combination of tactile laser optics and wire feed systems that have been continuously developed since 2001, together with our strong partner PT Photonic Tools GmbH. In the field of remote laser welding, we cooperate worldwide with the market leader Blackbird Robotersysteme GmbH and complement their innovative scanner optics and control solutions with ABICOR BINZEL's worldwide network of experts. In this way, we are able to guarantee our customers optimal worldwide support from laser application to service.

Reliable process monitoring and quality assurance

In order to continuously improve product quality and production processes, reduce costs and fulfil safety requirements, holistic solution approaches are needed. ABICOR BINZEL also offers a selection of globally proven technology packages for process monitoring and quality assurance so that the demanding quality requirements in production environments can be met and the economic efficiency of laser welding and laser brazing can be further optimised. Whether process visualisation, laser process monitoring or weld seam inspection, with our partner products from Lessmüller Lasertechnik GmbH, 4D Photonics GmbH and SmartRay GmbH you are on the safe side.

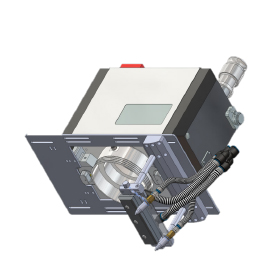

Process visualisation & process monitoring WELDEYE

No defect in the weld seam is missed by this "eye". The WELDEYE high-speed camera system visualises and monitors the welding or brazing process and supports quality assurance with industry-proven algorithms.

Laser process monitoring WeldWatcher®

The complexity of the production world continues to increase. This makes the monitoring of laser processes as part of quality assurance all the more important. With WeldWatcher®, defects in the weld seam can already be detected during welding, thus significantly reducing time-consuming and expensive inspections.

3D weld inspection JOSY

Whether gas-shielded welding or laser joining, quality assurance is becoming increasingly important in automated processes. With this high-speed all-in-one system, costly quality incidents can be avoided and rework costs significantly reduced. The JOSY non-contact optical 3D inspection turns planned safety into tested and documented safety. [ more information ]