Tungsten Electrodes

The nuts and bolts for best welding results

For tungsten inert gas welding (TIG), the non-fusing and temperature resistant tungsten electrode, in addition to the torch, the energy source and the inert gas, is a major factor for obtaining optimum results.

The following must be taken into consideration when selecting the tungsten electrode:

- Type of tungsten electrode

- Diameter of electrode

- Quality of the polished section and roughness of the electrode

- Tip geometry of the electrode

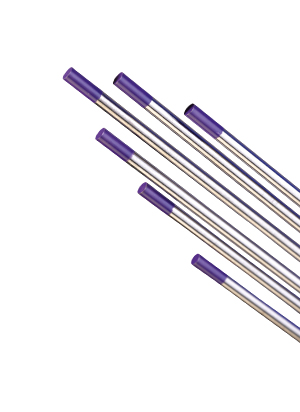

E3® Electrodes

Electrodes with rare earth (mixed oxides). In comparison to thoriated electrodes this electrode is less harmful to the environment and not radioactive. The electrodes offer excellent ignition characteristics and consistent welding properties. They are universal and suitable for all applications in the whole range of DC and AC welding for non-alloyed and high-alloyed steel, aluminium, titanium, nickel, copper and magnesium alloys. Because of their great ignition properties they are also suitable for automated welding. Due to the low electrode temperature, they offer an increased current carrying capacity and longer service life than thoriated electrodes.

Colour-coding:

E3® = Purple

WLa Electrodes

Lanthanated electrodes are suitable for applications in DC and AC welding. Their main areas of application are the welding of non-alloyed and high-alloyed steel, aluminium, titanium, nickel, copper and magnesium alloys. These electrodes are also suitable for the use in micro-plasma welding.

Ignition characteristics are enhanced with increased amounts of lanthanum oxide (La2O3). The overall service life and current carrying capacity is lower than the E3® electrodes.

Colour-coding:

WLa 10 = Black

WLa 15 = Gold

WLa 20 = Blue

WCe Electrodes

By adding cerium oxide (CeO2), these electrodes have an increased capacity compared to pure tungsten electrodes, however the WCe electrodes have a lower capacity than the E3® and WL electrodes. Main areas of application are in the DC and AC welding of non-alloyed and high-alloyed steel, aluminium, titanium, nickel, copper and magnesium alloys in the low and middle current range.

Colour-coding:

WCe 20 = Grey

WP Electrodes

Undoped electrodes – consist of pure tungsten. The main area of application for this type of electrode is the AC welding of aluminum alloys with excellent arc stability. The WP-electrodes are not suitable for DC welding.

Colour-coding:

WP = Green

WZr Electrodes

Tungsten electrodes with the addition of zirconium have a lower risk of contaminating the weld from deposits of tungsten. The main area of application for this electrode is AC welding. They are limited in their suitability for DC welding.

Colour-coding:

WZr 08 = White