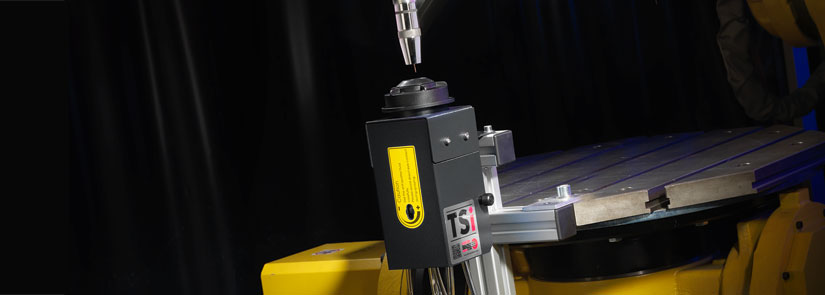

Cистема автоматизированной замены мундштуков горелок TSi

Plug & Spray …

The TSi from ABICOR BINZEL – the stand-alone welding torch injection unit for simple integration in existing or new processes. The spray pulse is triggered by the integrated activating mechanism as soon as the welding torch is moved into the TSi vertically up to the spraying position. This makes a complicated electric actuator or integration in the robot controller unnecessary.

In addition, the TSi scores with an economical and environmentally-conscious spraying process. The sealed spraying chamber prevents the antispatter fluid from escaping during the spray pulse and the infinitely variable spray fluid setting ensures correct dosing. Both enable the lowest possible consumption of anti-spatter fluid and increase a safe and clean welding work environment.

Along with these properties, the TSi guarantees the familiar and even coating of the cleaned welding torch inside and out – with ABICOR BINZEL's tried and tested anti-spatter fluid and in this way prevents weld spatter from sticking.

The TSi stands for simple integration in the welding process, reliable welding torch maintenance and the efficient and environmentally-conscious use of anti-spatter fluid.

Arguments that speak for themselves:

- Simplest starting – electric actuator not required

- Spray pulse activated by the robot movement

- No complicated integration into the robot controller

- Sealed and highly efficient spraying process – no overspray

- Clean and safe welding environment

- Low consumption of the anti-spatter fluid

- Plug & spray – means just what it says

Technical data

General information

| Weight: | 1.5 kg (without anti-spatter fluid) |

| Ambient temperature in operation: |

0 °C to +40 °C |

| Relative humidity in operation: |

up to 90 % at 20 °C |

Pneumatic connection

| Connection port: | Ø 8 mm |

| Operating pressure: |

min. 0.5 MPa up to max. 0.6 MPa |