MIG/MAG Welding Torch System ROBO WH and ROBO WH-PP

Quick adaptation to changing welding tasks …

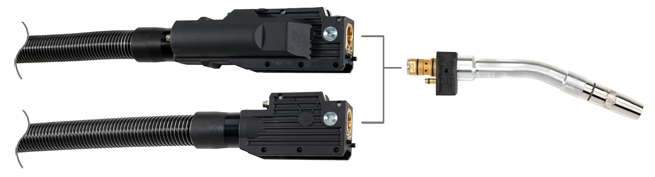

The air cooled MIG/MAG neck change welding torch system WH / WH-PP enables the complete torch neck to be replaced either manually or automatically – thanks to the innovative interface technology on the change body. This means torches of the same design can be replaced in seconds for maintenance purposes, or torches with special geometries for different welding positions can be changed as required.

Equally, the replacement of contact tip and gas nozzle and the monitoring of the TCP also take place outside the welding cell, thus increasing the availability of the system and reducing downtimes.

Advantages that speak for themselves:

- Fast torch neck change and replacement of wear parts increase system availability

- Flexible adaptation to changing welding tasks

- Also available as a push-pull system for precise wire feeding

- Air cooled up to 360 A

Degree of automation: High

Application areas:

- Automotive construction

- Automotive suppliers (Tier 1, Tier 2)

- Commercial vehicle construction

- Earth-moving equipment

- Rail vehicle construction

- Machine and steel construction

Material:

- Construction steels (coated / non-coated)

- Chrome-nickel steels

- Duplex steels

- Nickel basic materials

- Mixed compounds

- Aluminium materials

- Magnesium materials

- Copper materials

- Special materials

Robot interface:

- Conventional robot (Cable assembly external):

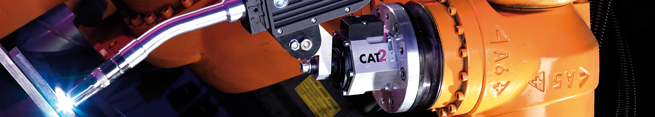

– Robot mount CAT2

– Fixed bracket RTM - Hollow wrist robot (Cable assembly internal):

– Robot mount iCAT

– Bracket iSTM (for robots with integrated collision software) - Hollow wrist robot (Cable assembly external):

– Robot mount CAT2

– Fixed bracket RTM

ROBO WH A 360 and ROBO WH-PP A 360 (air-cooled)

Technical data according to EN 60 974-7:

Cooling: air-cooled

Rating: 300 A CO2 / 250 A Mixed gases M 21 according to DIN EN ISO 14175

Duty cycle: 100 %

Wire-Ø: 0.8 - 1.2 mm

ROBO WH A 500 and ROBO WH-PP A 500 (air-cooled)

Technical data according to EN 60 974-7:

Cooling: air-cooled

Rating: 360 A CO2 / 290 A Mixed gases M 21 according to DIN EN ISO 14175

Duty cycle: 100 %

Wire-Ø: 0.8 - 1.2 mm