NovEye™ Autonomy: Pipe welding with AI

Get better and better – like a welding specialist: Enter a new era of fully automated MIG/MAG pipe welding with this AI learning software that controls the course of the weld pool as a human would, while increasing productivity and delivering X-ray quality welds.

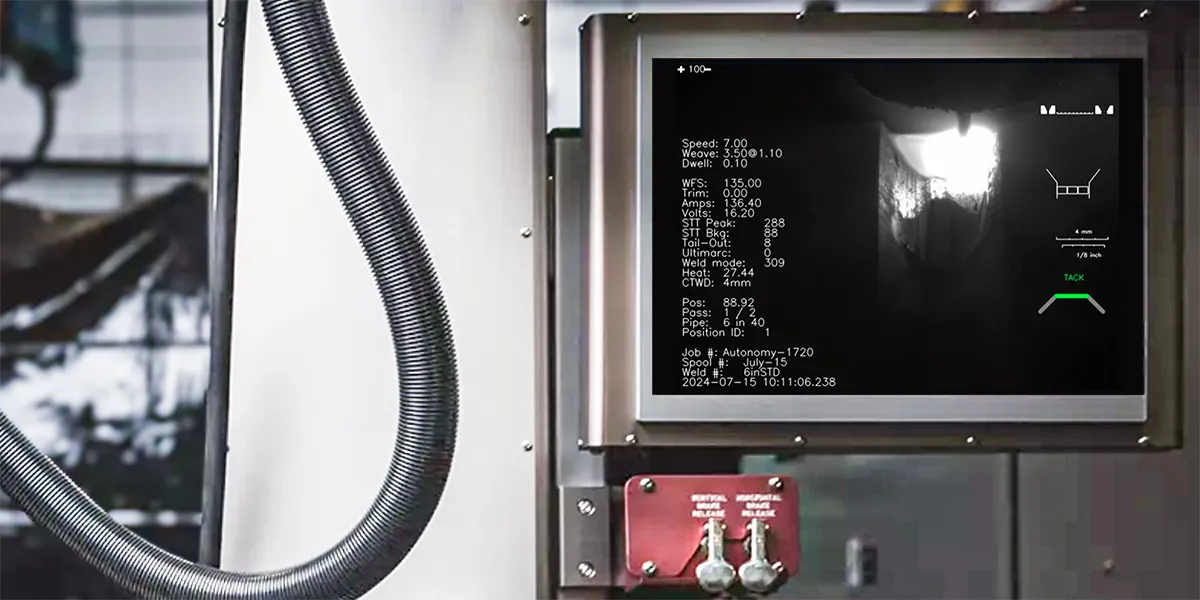

The operator can take care of other tasks while the spool welding robot SWR with its NovEye™ Autonomy system takes care of controlling the automated pipe welding process.

All information at a glance

First of its kind in welding

In cooperation with ABICOR BINZEL, Novarc Technologies introduces NovEye™ Autonomy. NovEye™ Autonomy represents a cutting-edge computer vision and image processing system, which combines sophisticated AI algorithms with advanced robotic controls to fully automate pipe welding, boosting productivity while ensuring X-ray quality welds.

Harnessing extensive data collection and deep learning, this revolutionary software integrates with the robot's control system, managing the weld pool just like a human welder. This allows the robot to take over monotonous and repetitive welding tasks.

Software specifications

- Immediately detects and adapts welding parameters to maintain weld integrity

- Delivers a perfect root pass by controlling the weld and motion parameters against changes in gap, hi-lo, and out of round pipe

- Automatically detects tacks and adjusts welding and motion parameters simultaneously to give you the perfect tack fusion

- Has an automatic root gap adaptation function that handles various rout gaps »en route« to your multi-pass and multi-layer automated weld

- Gets smarter by collecting weld data and continuously improves through a terabyte-scale library of welding videos

Plan features NovEye™ Autonomy

| Features |

|

| Weld monitoring |

|

| Seam tracking |

Autonomous, in real-time:

|

| Root save | Autonomous adjustment of weld parameters to adapt to the gap width changes in real-time |

| Tack adaption | Autonomous tack detection and fusion in real-time to ensure weld quality |

| Upgrade |

|

- Fully autonomous welding process from root to cap with non-stop welding

- Zero operator intervention

- Real time vision processing

- Learns from successful and failed welds and will continue to improving over time

- Simply fit the pipe on the positioner, hit “Start weld“, NovEye™ Autonomy takes care of the rest allowing the operator to working on other tasks

- X-ray quality welds every single time