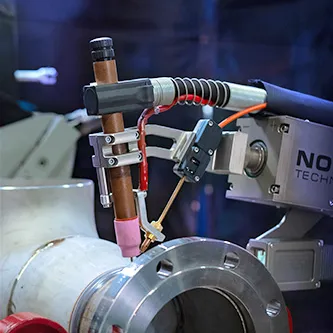

Pipe welding robots

Welding pipes has never been easier or more economical. Here you will find highly efficient pipe welding robots for MIG/MAG and TIG applications.

Why use pipe welding robots?

When it comes to pipe welding, quality and adherence to deadlines count. And it is becoming increasingly difficult to find skilled welders. Welding pipes is a tough job. Layer by layer has to be welded precisely. Depending on the size and wall thickness of the pipes, filling a gap is very time-consuming and physically exhausting. These welding robots specially designed for pipes take over this work and weld from root to cap – with consistent quality and incredible speed. The weld seams are of X-ray quality!

How fast does a pipe welding robot weld?

Compared to manual welding, an SWR MIG/MAG pipe welding robot welds unalloyed steel 3–5 times faster and stainless steel up to 12 times faster. A TIG welding robot SWR TIP TIG® welds 2.6 times faster. If you have several positioners in use, one person can operate up to 5 positioners. This means that several pipes can be welded one after the other with minimal downtime and handling requirement's. With over 60 pre-programed weld recipes included within the SWR, you can move between weld stations and begin welding again with as little as 3 minutes meaning your arc time is maximized to over 90 %

per shift.

Is it worth investing in a pipe welding robot?

A SWR spool welding robot welds approximately 3 to 12 times faster than a welder, depending on the application. You will never have to turn down large orders again. The setup for a welding job is done quickly. Even the welding of many joints can be completed with comparatively little space requirement. Depending on the frequency of use, a spool welding robot SWR for example pays amortizes within 6–18 months.

How much space does a pipe welding robot need?

The footprint of a SWR is 1.2 m x 1.2 m. This pipe welding robot can be positioned anywhere in a work hall with a height of 5 meters. It is freely accessible from all sides. Its working area is 330 °.

What materials can a SWR welding robot weld?

A MIG/MAG spool welding robot SWR welds black steel, low-alloy steels, stainless steel and nickel alloys. A TIG SWR welds carbon steel, stainless steel, duplex steel, super duplex, plus many more.