Non-flammable anti-spatter spray

When welding with the MIG welding process or the MAG welding process, welding spatter inevitably occurs. These hot particles stick to the workpiece and to the front end of the welding torch – and especially to and inside the gas nozzle – if this is not prevented right from the start. On the one hand, excessive welding spatter can be prevented by setting the welding current correctly on the welding device or by ensuring sufficient shielding gas coverage. On the other hand, special anti-spatter sprays prevent weld spatter from sticking. For example, welding spatters on the workpiece can be removed quickly and easily with a cloth or hand brush – without time-consuming grinding. This considerably reduces the need for reworking, e. g. before painting resp. finishing.

The Super Pistolenspray NF from ABICOR BINZEL is an anti-spatter spray that can be used for the wear parts gas nozzle and contact tip as well as for the workpiece itself or even the clamping element. NF stands for »non flammable«. Thus, the Super Pistolenspray NF meets the highest possible safety requirements and delivers the best welding results.

The anti-spatter agent Super Pistolenspray NF is the all-in-one solution for welding torch, workpiece and safety – all from one can!

Why Super Pistolenspray NF?

Welding spatter cannot be prevented during MIG welding and MAG welding. However, if weld spatter is burnt onto the workpiece, it must be removed before further processing. This process is laborious, time-consuming and cost-intensive. In the worst case, the workpiece even has to be discarded. Welding spatter in and around the gas nozzle prevents the gas from flowing laminarly into the welding process and thus causes gas turbulence. This can lead to oxygen from the atmosphere entering the process, which in turn can show up in the formation of pores in the weld seams. Welding spatter on the outside of the contact tip can also have a negative effect on the shielding gas flow. If these are even on the front end, the wire feed can be disturbed and so-called sticking can occur. The contact tip can no longer be used and the process must be interrupted.

However, it is possible to reduce the formation or sticking of welding spatter on the workpiece and on the front end of the welding torch – with just one product: the Super Pistolenspray NF from ABICOR BINZEL.

Few residues – less reworking

Applied to the workpiece, this anti-spatter spray leaves almost no residue compared to competitor products, depending on the process, material and quantity applied! After welding, workpieces are further processed and for example prepared for painting. With Super Pistolenspray NF, reworking after welding is reduced to a minimum, which saves time and thus costs. Welding spatters can be removed quickly and easily with a cloth or hand brush – without time-consuming grinding.

An additional advantage: Like all ABICOR BINZEL anti-spatter liquids, the Super Pistolenspray NF is absolutely silicone-free! This is important especially if the components will be painted later on, as silicone residues can lead to adhesion problems when coating or painting.

Although the Super Pistolenspray NF is very productive, the ABIBLUE NF anti-spatter liquid from ABICOR BINZEL is recommended for spraying workpieces with large surfaces. Through its blue colour indicator, this anti-spatter spray immediately indicates how well the workpiece has been moistened with the liquid – and it can also be removed easily and residue-free.

Effect of Super Pistolenspray NF

Super Pistolenspray NF forms a protective film on the wetted areas and prevents weld spatter from sticking or burning in deeply. The applied protective film remains firmly attached to the gas nozzle and the contact tip in every holding position or angle of the torch. Some of the welding spatter bounces off directly, spatter stuck in the gas nozzle or contact tip can be easily knocked off or removed with Co2 pliers (cleaning pliers). The Super Pistolenspray NF can considerably extend the service life of wear parts such as the gas nozzle and contact tip.

Super Pistolenspray NF in Action …

Fields of application of the ABICOR BINZEL anti-spatter sprays

Spraying the gas nozzle and contact tip or the workpiece in enclosed spaces is expressly permitted with the anti-spatter liquid Super Pistolenspray NF. For example, it is mainly used in tank construction and shipbuilding as well as in parts production without sufficient ventilation. In addition, this anti-spatter spray can also be used in all production facilities and countries where flammable anti-spatter liquids are generally prohibited. Of course, Super Pistolenspray NF can also be used as an anti-spatter agent in all well-ventilated welding processes.

Composition of Super Pistolenspray NF

The basic component of the Super Pistolenspray NF is an aqueous emulsion of vegetable oil. Therefore, this anti-spatter spray is not subject to any special safety regulations – neither for its use, nor for its transport by land or sea, nor for its storage.

The Super Pistolenspray NF is neutral to the welding process and even contains corrosion protection. It can be applied to the gas nozzle and contact tip of the welding torch to protect against spatter and corrosion, as well as to the workpiece – and also to the clamping device holding the workpiece.

The difference to other manufacturers can be seen directly in the weight of the 400 ml Super Pistolenspray NF can: each can contains the anti-spatter agent as the main ingredient, not the propellant as in almost all flammable products, and is therefore noticeably heavier in comparison. This means that the 400 ml can of Super Pistolenspray NF continues to spray metre after metre even when other anti-spatter sprays have long since been used up.

The properties of the Super Pistolenspray NF to the point:

- Non-flammable according to ABICOR BINZEL NF standard

- Silicone-free, wax-free and water-soluble

- No danger during transport, storage and processing

- Neutral towards the welding process

- Equipment and surfaces additionally protected by corrosion protection

- Spray behaviour optimised for workpiece and gas nozzle

- More usable anti-spatter spray with the same can content compared to the competition

- Less residue on the workpiece than with competitor products enables faster further processing such as finishing

- Excellent results with stainless steel welding

- Not suitable for aluminium

ABICOR BINZEL NF standard: Super Pistolenspray NF

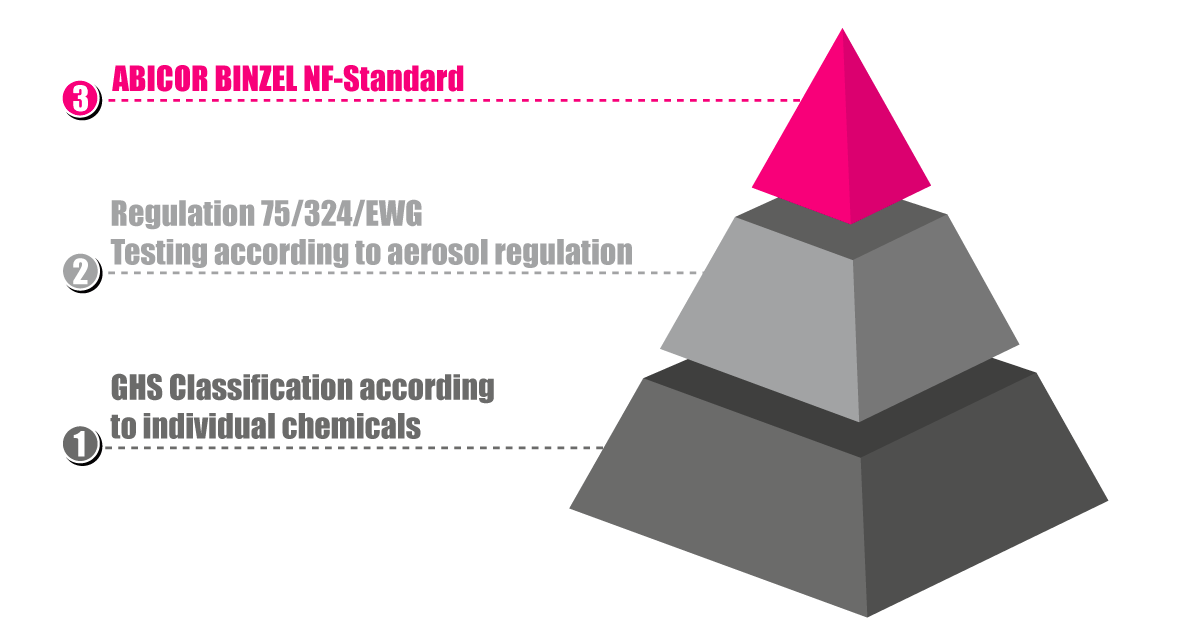

Safety for the welder is a top priority at ABICOR BINZEL. For this reason, our own standard of non-flammable NF products, such as the Super Pistolenspray NF, is above the legal regulations and standards.

In the GHS (Globally Harmonised System) a classification is made according to individual raw materials of the total product with regard to the hazardous substance labelling. In the test according to the Aerosol Directive (Council Directive 75/324/EEC on the approximation of the laws of the member states relating to aerosol dispensers), the incombustibility of the anti-spatter product as a whole is verified by a flame spray test and a barrel test.

The ABICOR BINZEL NF standard exceeds this directive 75/324/EEC by far, because all ABICOR BINZEL products marked with this name suffix »NF« were able to prove their non-flammability under various practical conditions in additional, standardised welding tests. For the welder – as well as the production itself – this means absolute security that nothing around will suddenly catch fire or that release agent cans will unintentionally burst into flames.

With the Super Pistolenspray NF from ABICOR BINZEL, production companies are on the safe side with regard to non-flammability and on top with regard to the welding result!