Robot Periphery

Every robot welding torch needs excellent peripherals to be perfect. An inferior robot mount, for example, is a real danger for the robot torch. In the event of a collision, damage to the welding robot and the entire torch equipment can quickly occur. ABICOR BINZEL robot mounts are reliable, provide safety and prevent damage to the welding robot.

Reliable wire feeding makes a significant contribution to ensuring that the welding wire can be fed into the process with as little friction as possible and ensures a good weld seam. This is what the ABICOR BINZEL MasterLiner stands for. No twisting, no sticking, no abrasion.

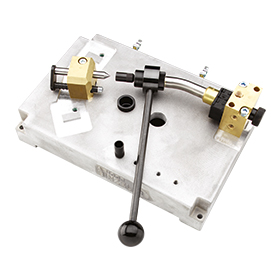

Automated replacement and, ideally, cleaning of robot torches saves valuable time. With the torch neck exchange and torch cleaning stations from ABICOR BINZEL, torch necks can be changed smoothly - including cleaning of spatter build-up and re-spraying with anti-splatter protection, depending on the device type.

What is the advantage of torch cleaning stations/torch exchange stations?

A robotic welding torch must weld continuously. Maintenance of a robotic welding torch should be avoided wherever possible. However, even the best-cooled system must be serviced at a time X, but the time for this must be kept as short as possible. This is best achieved with a torch exchange system. Torch cleaning stations not only change the robot torch necks, but also remove adhering welding spatter at the same time. And anti-spatter protection is also applied directly. All this happens while the robot is already welding again with the new robot torch neck. Torch cleaning stations and torch neck exchange systems therefore save time and money. Both factors that increase the efficiency of welding robots.