3D weld inspection MICO – reaches every welded seam

The most compact and narrowest sensor head on the market, setting the new benchmark

Today's sensors for non-destructive automated weld inspection are already very good in their development. Very often, however, a robot-assisted inspection of weld seams cannot do without additional control. In most cases, 5-10 % of the seams cannot be inspected automatically because they cannot be reached by the inspection optics. These must be monitored by additional workers. With the 3D weld seam inspection MICO from SmartRay GmbH, this is now changing. MICO has a uniquely compact sensor head and makes accessible what was previously inaccessible. A real game changer in the end-of-line inspection of tomorrow.

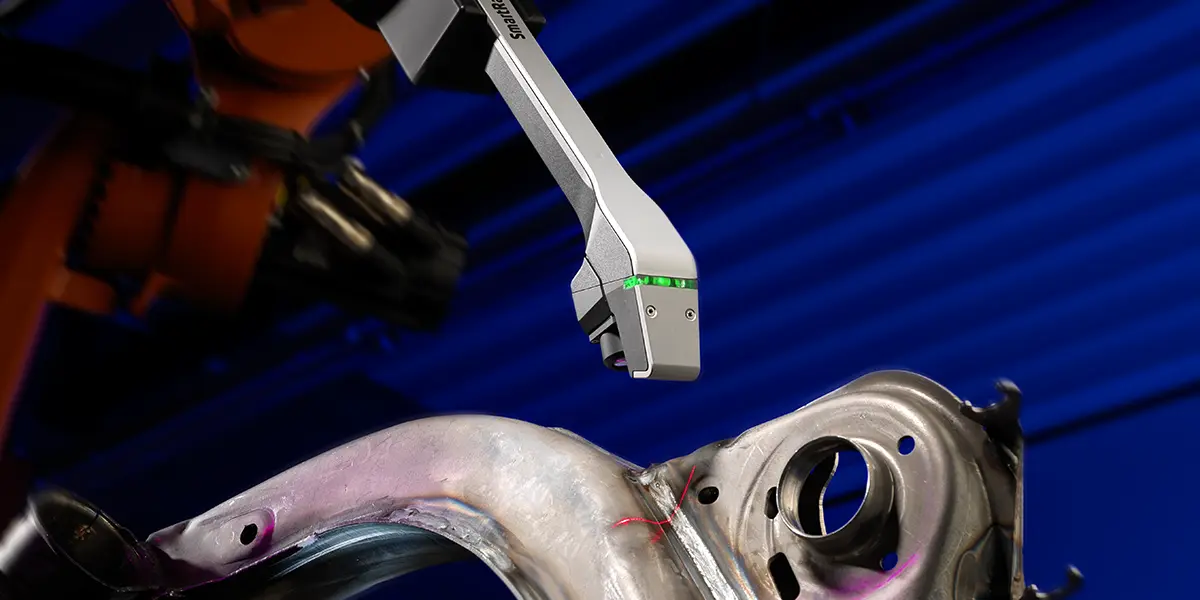

Every set weld seam can be inspected by the MICO 3D weld inspection. With this innovative, lance-shaped sensor design, you achieve maximum reachability in your material inspection, which has never been seen before. Such a compact sensor is unique on the market!

Another advantage: With MICO, you drastically reduce your rework costs. Defective weld seams are precisely visualised and can be reworked in a targeted manner.

If you manufacture products or components with many weld seams, you know the problem with materials testing: not every welded seam can also be inspected automatically. To inspect these, you need a separate inspection strategy, such as an additional visual inspection. Depending on the number of weld seams per component, this is an additional process that means more effort and thus more costs.

The 3D inspection system MICO solves this problem right from the start. This sensor has the same reachability as a standard MIG/MAG welding torch. The design is comparable to a robot welding torch with a very compact optic. The electronics are separated from the optics. In this way, it reaches exactly wherever a weld is made.

The non-destructive 3D inspection sensor MICO is not only the smallest and thinnest weld inspection sensor with the best reachability currently available on the market. It is also 50% faster to inspect than other sensors on the market. With approx. 3-4 kHz, this system makes 3,000-4,000 profile cuts per second.

This means: Currently you inspect 130 mm/s with the standard inspection process of your previous system. With the MICO sensor, you can achieve 200 mm/s. Thus, you can inspect more welds in a short cycle time with only one inspection system – 100%. With several inspection systems, you thus have the option of even reducing the number of your systems or inspecting significantly more seams in the same cycle time with one MICO system.

With the 3D sensor MICO, you optimise your quality assurance and increase your productivity and efficiency.

Unique reachability

Its lance-shaped design, inspired by a welding torch, gives the 3D sensor MICO incomparable reachability. In addition, the welding torch and the MICO inspection system have the same tool centre point (TCP). The working point of both tools is therefore identical. This means: every seam that you weld on your products or components can also be inspected with the 3D inspection sensor MICO.

Based on the same envelope curve and TCP, you can also achieve considerable synergies in the simulation of the welding and inspection process as well as in offline and online robot programming.

Due to its thin and compact shape, this inspection sensor enables you to inspect your weld seams even in places where automated inspection was not possible before.

High-resolution high-end system

With a field of view of 40 mm, the very small, compact sensor head for weld seam inspection has a resolution of over 1,000 pixels. This means that the lateral resolution is 40 µm. Figuratively explained: the distance between the measurement data is smaller than the diameter of a human hair with approx. 70 µm.

Very good standard systems for inspecting weld seams detect pores up to 0.3 mm in size. With the 3D weld inspection MICO, you can detect pores of up to 0.2 mm. This higher resolution is more than you need for classic MIG/MAG welding applications. Thus, you can reliably find even very small defects in the weld seam – and about 50 % faster than with previously known systems.

Strictly speaking, the MICO inspection sensor has such high resolution and speed that it is also suitable for inspecting laser-welded seams.

Attachment to robot

Like a robot welding torch, you can also attach the 3D sensor head MICO directly to a hollow-arm robot. Therefore, you do not need any special mounts in an individual design as an additional element. This reduces the required equipment by one component and cuts implementation costs

Mount with collision protection possible

You can also adapt the MICO sensor head directly to the iCAT robot torch mount with integrated switch-off protection from ABICOR BINZEL. In the event of a collision or unintentional scraping of the component, iCAT switches off the robot. In this way, further damage to the sensor system is prevented.

Internal cables for more room to manoeuvre

MICO is the only optical inspection sensor on the market with internal cabling through the hollow axis of the robot. This significantly minimises the cable load and, in particular, avoids the interference contour of an external cable connection.

All cables for the electrics run inside the sensor head and also continue internally in a TA robot arm – through arm = cable assembly guide through the robot arm. The cables are resistant to bending and torsion. The same applies to the plug connections, which also guarantee good strain relief. All in all, this means that with the 3D sensor MICO you can reduce all cable repairs to a minimum for cable maintenance.

The 3D weld inspection MICO is also available for OA robots – over-arm welding robots – i. e. for robots with externally guided cable assembly.

Modular cable concept

You can divide the cabling of the 3D weld inspection MICO within the robot arm into small segments if required. The modular cable concept allows you to replace a cable section that is under constant heavy load more quickly and easily if necessary. All in all, with MICO you have a very repair- and maintenance-friendly system for your automated weld seam inspection.

Solution package ABICOR BINZEL & SmartRay

If quality assurance is indispensable for your production lines, you have forward-looking and reliable systems with the solution packages from ABICOR BINZEL and SmartRay. The high-performance, convincing technology of SmartRay for end-of-line inspection processes reaches your production facilities without long detours through the international sales and service network of ABICOR BINZEL. Worldwide.