Fume Extraction System xFUME® FLEX

The mobile all-rounder for fume extraction

Occupational health and safety is a top priority in gas-shielded metal arc welding (GMAW). Since the International Research Institute of Cancer (IARC) classified welding fumes as carcinogenic to humans in 2018 (IARC Monograph 118), the regulations regarding occupational safety for manufacturing companies are often much stricter. Welding fume extraction systems are now part of the basic equipment of every welding workplace. A flexible and versatile extraction system for the efficient capture of welding fumes is the xFUME® FLEX from ABICOR BINZEL. This mobile welding fume extraction system can be easily integrated into any manual welding workplace, as no special fume extraction torches are required.

All information at a glance

- Task of a welding fume extraction system

- Extracting welding fumes with the xFUME® FLEX

- xFUME® FLEX equipment incl. extras

- The advantages of the xFUME® FLEX at a glance

- Advantages of an extraction arm/LEV system

- Filter performance of the welding fume extraction system xFUME® FLEX

- Find a suitable welding fume extraction system

- Blogs about welding fume extraction

- Technical data

- Videos about welding fume extraction

- Documentation

Task of a welding fume extraction system

A device for capturing welding fumes must efficiently and reliably extract harmful fumes so that these do not enter the welder's respiratory tract. Ideally, all those working in the vicinity of the welder are also protected from exposure to welding fumes. The welding fume extraction system captures the welding fumes produced and directs them into the extraction system. A pre-filter and a main filter clean the fumes and release the clean air into the environment. Instead of a common carbon brush motor, the xFUME® FLEX is equipped with a brushless motor, which considerably extends the service life of the motor.

A major advantage of the xFUME® FLEX is that the system not only extracts welding fumes from the ongoing process, but also any kind of micro-particles that are produced by cutting and grinding work, for example. Thus, the xFUME® FLEX is a true all-rounder in terms of extraction.

The xFUME® FLEX is a so-called LEV system – Local Exhaust Ventilation – a local welding fume extraction system with movable extraction arm and extraction hood. This extraction system is a cost-effective and at the same time easy start into welding fume extraction, because an investment in special fume extraction torches is not necessary with the xFUME® FLEX and the already existing equipment can be used without restriction.

As a mobile extraction system for welding, the xFUME® FLEX is ideally suited for mobile use at changing individual workplaces. It operates under alternating current at 230 or 115 volts and can be easily connected to a socket. Its freely movable extraction funnel can be easily positioned above any welding workstation and efficiently extracts the welding fumes. Correctly positioned, the xFUME® FLEX captures more than 90 % of the welding fumes. The LED work light, integrated as standard, ensures optimum illumination of the workpiece.

The welding fume extraction system xFUME® FLEX is a compact, mobile extraction unit that allows easy transport to the workplace. Equipped with an extraction arm in two, three or four metres length, the extraction hood can easily be placed directly above the welding process. In addition, the xFUME® FLEX is equipped with a brushless and therefore durable motor as well as an easily replaceable filter. Due to its filter surface, which is on average three times larger compared to commercially available standard extraction systems with an extraction arm, the filter is more absorbent and therefore needs to be replaced less often. Thus, the operating costs are significantly lower than with many other devices.

Where other LEV systems offer optional or no features at all, such as an illuminated extraction hood or protective grids for the extraction hood, the xFUME® FLEX includes a powerful LED work light and a grid as standard to protect against larger foreign particles.

The advantages of the xFUME® FLEX at a glance:

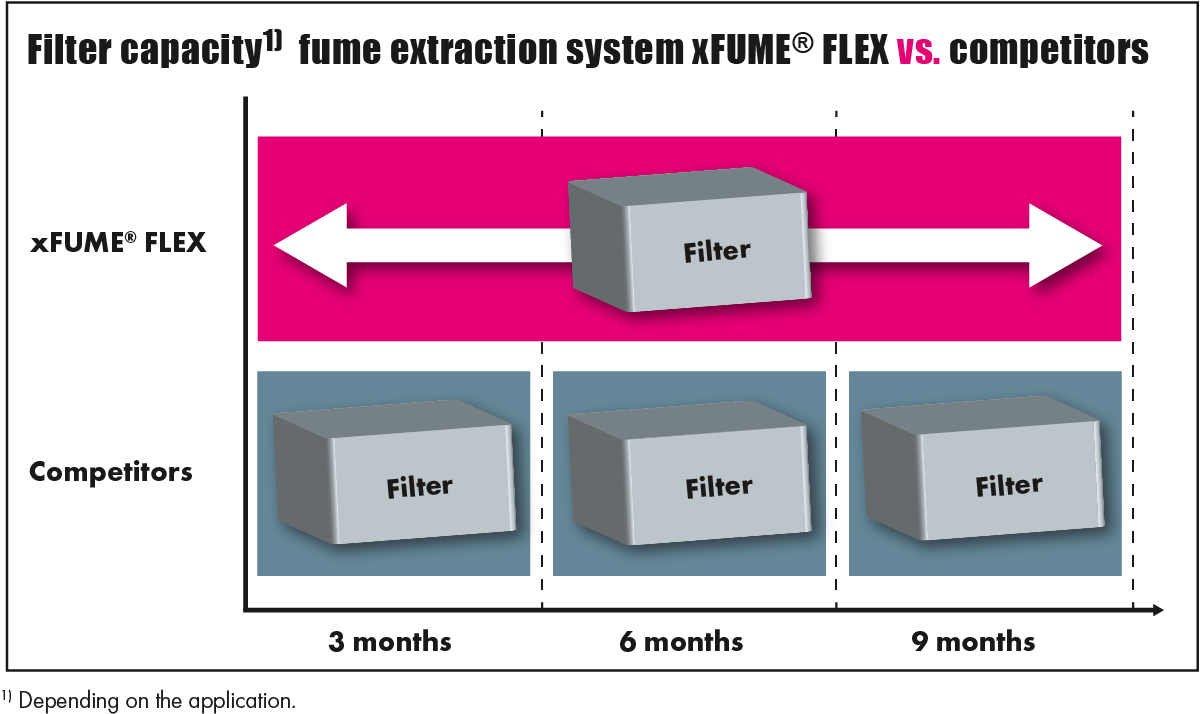

- Extra large filter surface guarantees three times longer service life compared to commercially available standard extraction systems with extraction hood

- 2, 3 or 4 m long extraction arm enables precise positioning of the extraction hood

- Powerful LED work light on the extraction hood in the standard version ensures optimum illumination of the workpiece

- Compact, mobile design facilitates easy transport to the workplace

- Brushless motor guarantees long service life

- Easy to connect to 230 or 115 volt sockets

The LEV system or the extraction of welding fumes with an extraction arm is a simple, low-cost and effective entry-level solution for local fume extraction, because nothing has to be changed neither in the welding process nor in the working environment. All previously used welding torches can still be used.

Another advantage of extraction hoods and extraction arms is that they can also be used for TIG welding and plasma welding. Although only very few gases are produced during TIG welding, these are also efficiently captured with an extraction hood and this avoids the need to invest in a special and expensive TIG extraction system. LEV systems are therefore a cost-effective all-rounder solution for MIG welding, MAG welding, TIG welding and also plasma welding.

Every extraction system – including the xFUME® FLEX – is exposed to a large so-called filter surface load. Compared to a high vacuum system, which can take up approx. 120 m3 of air, the xFUME® FLEX takes up 1,000 m2 of air – the surface of the filter, which captures and filters the extracted gases, must be correspondingly large. The surface of the xFUME® FLEX filter measures 36 m2 and is therefore three times larger compared to commercially available standard extraction systems with extraction hood and can be used accordingly longer.

Find a suitable welding fume extraction system

When searching for a suitable welding fume extraction system, usually the technical data of several manufacturers are compared, similar to the selection of other technical devices:

- Motor power – Is the device powerful enough for the requirements?

- Required voltage - Is the required power connection available?

- Maximum volume flow – Is the extraction capacity sufficient for the requirement?

- Maximum negative pressure – Is the extraction capacity at the required static pressure level?

- Dimensions – Can the extraction system be easily positioned at the manual welding station?

- Weight of the device – Can the extraction device be easily transported to a workplace?

- Extras – Are additional features that facilitate welding included or optional purchases?

Three points immediately stand out in a direct comparison with other manufacturers of mobile extraction systems. Compared to the usual market standard, the xFUME® FLEX provides:

- three times larger filter surface ► means the filter has to be changed three times less and the service life is three times longer, resulting in significantly lower operating costs.

- working LEDs included ► easier welding right from the start, no optional purchase required

- protective grid on the exhaust hood included ► larger foreign particles are not accidentally extracted, no optional purchase required

The filter surface is not usually considered as a savings potential when buying a welding fume extraction system! The larger the surface of a particle filter, the more particles can be absorbed. In addition, the service life is extended because the filter can be used longer and needs to be changed less frequently. The filter of the xFUME® FLEX with a filter surface of 36 m2 is still in use when the second or even third filter of conventional extraction systems had to be replaced in the same period.

Therefore, the xFUME® FLEX with its special features is a good choice with low operating costs.

Blogs about welding fume extraction

- 5 mistakes to avoid with a fume extraction torch

- What you should consider with welding fume filters

- Differences in welding fume extraction torches: from the extraction nozzle to the cable assembly

- Extraction of welding fumes: regulations and protection

Find out more about fume extraction in our ABIBLOG.

Technical data

| Typ | xFUME® FLEX |

| Max. air flow: | ∼ 1,200 m3/h |

| Connections: | extraction arm |

| Connection diameter: |

170 mm |

| Max. vacuum: | _ |

| Noise level: | ≤ 72 dB (A) |

| Voltage: |

115 V 50/60 Hz 230 V 50/60 Hz – |

| Motor power: | 1,1 kW |

| Filter efficiency: | ≥ 99.95 % |

| Cleaning: | none |

| Automatic start/stop: | no |

| Adjustable air flow: | no |

| Weight: | 120.0 – 129.0 kg |

| Dimensions: | 700 x 700 x 1115 mm |

ROBiPAK with xFUME® PRO and xFUME® ROBO Extraction Kit

Explainer: xFUME® FLEX

Explainer: xFUME® ADVANCED

View more videos about fume extraction on the ABICOR BINZEL YouTube-Kanal.