3D Weld Inspection JOSY

Where product quality needs to show continuous improvement, automation processes need optimized, production costs possibly reduced and safety requirements met. In order to do so, reliable technology is required – such as the 3D weld inspection with JOSY. JOSY stands for JOining SYstems and is the high-speed all-in-one system for non-contact optical 3D inspection. This technology is ideal for all common joining techniques combining highly developed sensors, adaptable software and individual service into a performance package that works together optimally and effectively supports quality assurance.

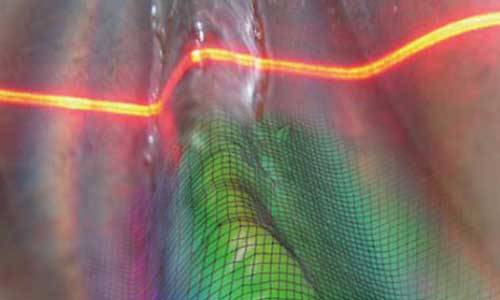

Geometric features such as cross-sectional areas, excess seams, seam transitions as well as welding defects such as pores, spatter, undercuts, top layer bulges and much more can reliably be detected and intuitively visualized with the JOSY 3D weld inspection. Up to now, these features and anomalies could often only be determined randomly through costly and sometimes destructive test procedures.

JOSY turns planned safety into checked and documented safety. It enables full control over every test process, increases the speed of the test processes, and significantly reduces rework costs. The advantage: sensors, software and service come from a single source – first-class quality »Made in Germany«.

Reliable quality check

Especially where welding is mainly done with robots – such as in the automotive industry – a 100 percent automated quality inspection is usually required. With the collected data and the extensive options for statistical analysis, you can keep an eye on the status of the production line. This enables better control of the processes compared to manual or destructive testing methods. Complex filter algorithms make it possible to reliably test even highly reflective surfaces.

Good workpiece accessibility

The compact size of the sensors shows outstanding advantages, especially when the accessibility of the seams is restricted due to the component geometry. Even difficult parts of the component, which are usually a challenge for the welding process, can be reliably checked for their weld seam quality.

Reduced downtimes

With the modular system concept, several test stations can be linked and thus provide an overview of the entire welding line. Test parameters can be adjusted offline on a central statistics computer where the changed parameters go through a validation process. They are then sent to the controller, which activates them after the next test cycle. In this way, downtimes are reduced to a minimum while the entire production line is kept in view.

For all robot types

The JOSY 3D weld inspection can be mounted on all common industrial robots such as Kuka, ABB, Fanuc, Yaskawa, Kawasaki etc. The broad portfolio of sensor models enables providing the right sensor for the application needing inspection. The scalable performance provides the highest level of accuracy in the results, which in turn can help reduce additional quality tests to a minimum.

Controller

- Compact, industrial design

- IP65

- Without fan, passively cooled

- Plug & play

- Integrated high-performance IPC

- Integrated PLC

- All common fieldbus connections

Fast fault detection and repair

The JOSY 3D weld inspection enables fast and reliable quality inspection of weld seams with a scanning speed of up to 400 mm per second. Faulty welds are detected directly and intuitively visualized in rework stations. With JOSY, expensive rework and rejects are reduced to a minimum.

- Simple handling, intuitive status monitoring and coordination of rework

- Test-, analysis- and statistic software all in one

- Complete monitoring process and documentation

- Template-based setup according to international test standards

- Pre-configured system allows short installation time

Geometric inspection characteristics

- Length

- Width

- Throat thickness

- Cross sectional area

- Toe

- Position

- Asymmetry & leg length

- Concavity, convexity

Visible welding faults

- Poren

- Makro Poren

- Mikro Poren

- Porosität (Porennester)

- Holes

- Undercuts

- Incomplete welds

- Incompletely filled groove

- Spatter

- Excellent accessibility thanks to its compact, robust and light design

- Up to 400 mm/s and 8 KHz high-speed weld seam inspection

- Powerful reflection filter

- Real-time images with a high dynamic range (HDR)

- Pore detection from 0.1 mm

- Variable laser classes (2/3R)

- Over 20 sensor models for a wide variety of applications

| SmartRay SR1200 | SmartRay ECCO 95 | |

| Scan rate: | 2 kHz – 4 kHz | 2 kHz – 8 kHz |

| Inspection speed: | 130 mm/s | 200 mm/s |

| Max. points 3D profile: | 480 | 1920 |

| Lateral resolution: | 39 µm – 75 µm | 5.8 µm – 70 µm |

| Weight: | 330 g | 490 g |

| Dimensions (volume): | 205 cm3 | 386 cm3 |

| Working distance: | 60 – 100 mm | 25 – 144 mm |

| Protection class: | IP 65 | IP 65 |

| Reflection filter: | ✓ | ✓ |

| Laser class: | 2 | 2 (optional 3R) |

Controller

| Design: |

Without fan, passively cooled Protection class IP 65 Integrierted UPS |

| Fieldbus interfaces: |

All common fieldbus systems (ProfiNet, ProfiBus, Ethernet) |

| Maintenance: | Active backups, remote access possible |