MIG/MAG Welding Torch System ABIROB® A ECO

Simple & effective ...

The ABIROB® A ECO product line – groundbreaking in its design, trend-setting in standardisation – guarantees consistent precision and an economic welding process thanks to its robust construction and simple handling.

Thanks to the innovative interlock system, the torch system allows a simple and fast change of cable assembly while the TCP remains the same.

Advantages that speak for themselves:

- Simple and compact modular design – easy to service

- Slim design – optimum accessibility

- High stability and reproducibility – maximum TCP safety even in the event of a “crash”

- Innovative interlock system – straightforward and fast change of the cable assembly with constant TCP

Typical areas of application:

- Automobile construction

- Suppliers (Tier 1, Tier 2)

- Bicycle industry

- Container construction

- Aerospace industry

Material:

- Construction steels (coated / non-coated)

- Chrome-nickel steels

- Duplex steels

- Nickel basic materials

- Mixed compounds

- Aluminium materials

- Magnesium materials

- Copper materials

- Special materials

Robot interface:

- Conventional robot (Cable assembly external):

−Robot mount CAT2

−Fixed bracket RTM - Hollow wrist robot (Cable assembly internal):

−Robot mount iCAT

−Bracket iSTM (for robots with integrated collision software) - Hollow wrist robot (Cable assembly external):

−Robot mount CAT2

−Fixed bracket RTM

Definition of the degree of automation:

Low = Torch neck change not possible

Medium = Torch neck change possible (manually)

High = Torch neck change possible (manually & automatically)

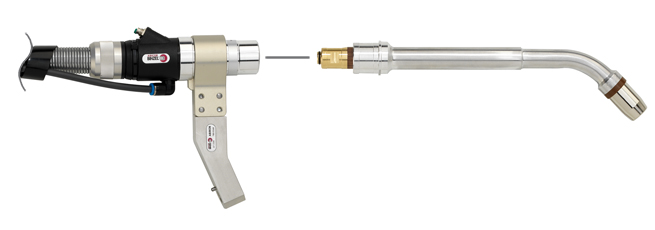

ABIROB® A 300 (gas cooled)

Technical data according to EN 60 974-7:

| Cooling: | gas cooled |

| Rating: |

300 A CO2 250 A Mixed gases M 21 (EN ISO 14175) |

| Duty cycle: | 100 % |

| Wire-Ø: | 0.8 - 1.4 mm |

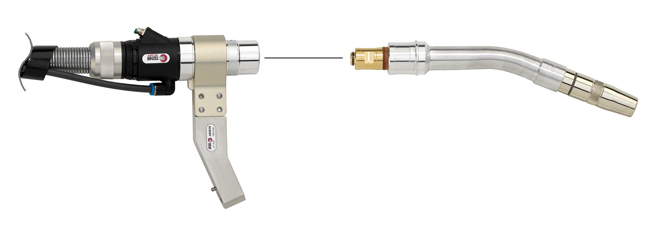

ABIROB® A 360 (gas cooled)

Technical data according to EN 60 974-7:

| Cooling: | gas cooled |

| Rating: |

360 A CO2 290 A Mixed gases M 21 (EN ISO 14175) |

| Duty cycle: | 100 % |

| Wire-Ø: | 0.8 - 1.4 mm |

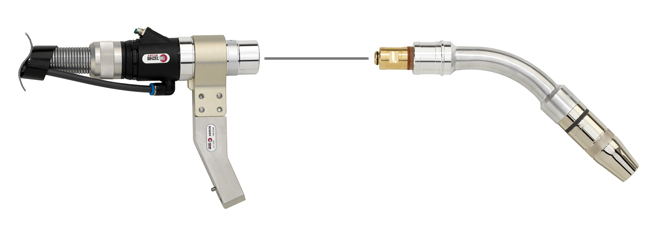

ABIROB® A 500 (gas cooled)

Technical data according to EN 60 974-7:

| Cooling: | gas cooled |

| Rating: |

500 A CO2 400 A Mixed gases M 21 (EN ISO 14175) |

| Duty cycle: | 100 % |

| Wire-Ø: | 0.8 - 1.6 mm |